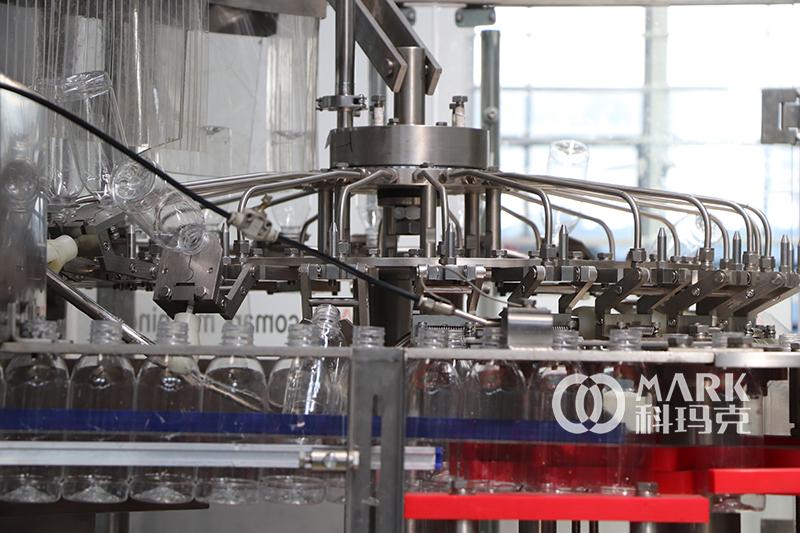

The machine combines washing, filling and capping three function in a body,used to produce plastic bottled still water,spring water,mineral water,purified water machinery. The whole process is automatic, Filling way using the gravity or micro pressure filling, make the speed is faster and more stable, so with the same model our machine output is higher and more efficient. The CGF series bottled water filling line can achieve different output: 2,000 / 4,000 / 6,000 / 8,000 / 10,000 / 12,000 / 16,000 /18,000 /20,000 / 24,000 BPH.

10,000BPH Still Water Filling Machine Whole Production Line

This CGF Wash-filling-capping 3-in-1unit:Beverage Machinery is used to produce polyester bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery.

Human machine interface touch-screen and PLC program make it a high degree of automatic production. All parts that have directly contact with the water are made of high quality stainless steel. The main electrical components are from international famous companies. such as Mitsubishi Schneider, Omron.

Bottle inlet 1. Adopt air conveyor system with high efficient filter to feed bottle, this can keep the inside of the filling machine clean 2. With bottle neck holding in the whole course and protect bottle block device. 3. The bottle feeding method with the air duct and the bottle feeding wheel directly connected. |  |

| Washing head 1. The rotary wheel is a fully stainless steel welded structure. 2. All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing. 3. The rinser is driven by driving system positioned inside machine frame via gear transmission. |

Filling head 1. Rotary wheel fully made of stainless steel SUS 304. 2. Filling valves are made of SUS316. 3. Filling valves are reasonably structured with accurate filling. 4. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth. |  |

| Capping head 1. Efficient centrifugal cap sorting method, with less cap abrasion. 2. Magnetic constant torque capping head, the capping effect is stable and reliable, and the capping defective rate is less than 0.2% 3. No bottle, no capping 4. High precision, stable. 5. All 304stainless steel construction |

PET bottle blow molding machine

1. Blow moulding machine 1,000-24,000bph, and 0.25-2L PET bottles are available.

2. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle, etc.

3. The man-machine interface is highly automated and easy to operate.

4. The compact machine occupies a smaller area.

Water treatment system

1. Pre-treatment system (water tank / multi-medium filter / active carbon filter / ion exchanger / precious filter)

2. Membrane separation system (ultrafilter / nanometer filter / RO reverse osmosis system)

3. Electrodialysis device / Sterilization system (UV device, ozone device) product water tank and so on.

Blow Dryer

1. This machine installed after the filling machine.

2. This machine is used to removing the water outside the bottle surface, the blowing capacity can be adjusted through the button.

Laser Printer Machine

1. Good beam quality, TEM00 single mode output, beam diameter 10mm after collimation, M2<1.3, beam divergence Angle 0.24mrad;

2. Main-oscillation power amplification technology without maintenance and pulse generation technology of seed light source;High reliability, average no fault

Automatic opp hot glue labeling machine

1. The machine can be used for various bottle types, such as: round bottle, flat bottle, and so on.

2. Labeling machine is controlled by PLC touch screen, all-electric eyes are using imported advanced configuration.

3. High speed, high accuracy, stable performance.

Automatic PE film shrink wrapping machine

1. PE film shrink wrapping machine is suitable for wrapping of such products as mineral water, bottles beer, drinks etc without bottom-tray (or with bottom-tray).

2. Working with PE shrink tunnel to pack the goods perfectly. The whole producing process adopt the Germany advanced technics.

By continuing to use the site you agree to our privacy policy Terms and Conditions.