Zhangjiagang Comark Machinery co.,ltd have 15+ years. For the water filling machine, we have water filling machine for pure water, mineral water, spring water and other bottled water, etc. The water filling machine adopts gravity filling principle. It adopts the technology of air conveyor direct connect with bottle infeed starwheel to instead of screw and conveyor. It is easier and more simple to change by bottle size, adopting neck handling technology to convey bottles from 200ml to 2L. If the neck is the same it can share one machine.

We can design the whole solution for water project

Experience of this filling machine since 2005

Long guarantee and long-time service

All main parts material are stainless 304 and 316

Main motor is ABB and SEW

Main electrical parts are supported by Siemens, Mitsubishi, Schneider

Our capping part adopts France “ZALKIN " technology

All parts of our factory adopt CNC for processing so precision is improved greatly

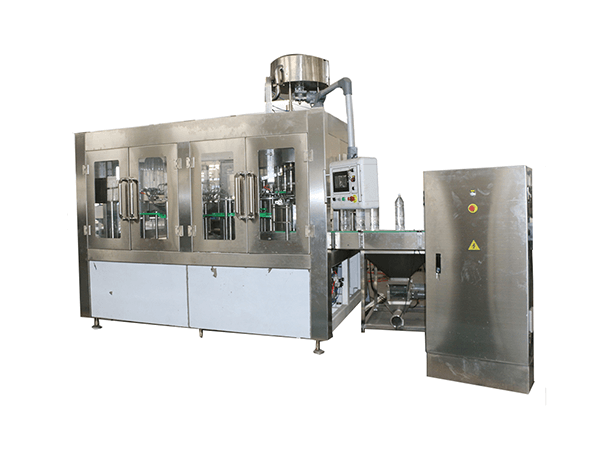

Washing Head: 8

Filling Head: 8

Capping Head: 8

Total Power: 2.8kw

Weight: 2000 KGS

Size: 1800x1400x2200mm

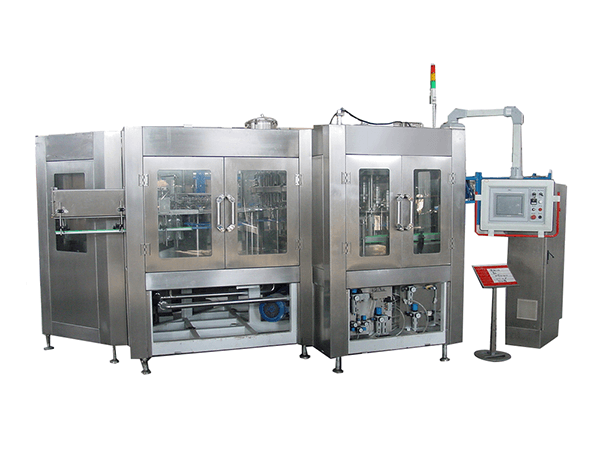

Washing head: 14

Filling head: 12

Capping head: 5

Total power:4.23kw

Weight:3000 KGS

Size : 2230x1630x2250mm

Washing head: 16

Filling head: 16

Capping head: 5

Total power:5.03kw

Weight:3500 KGS

Size: 2360x1830x2250mm

Washing head : 24

Filling head : 24

Capping head : 8

Total power:6.57 kw

Weight:4200 KGS

Size : 2900*2200*2250 MM

Washing head : 32

Filling head : 32

Capping head : 10

Total power:8.63 kw

Weight:6000 KGS

Size : 3800*2200*2250 MM

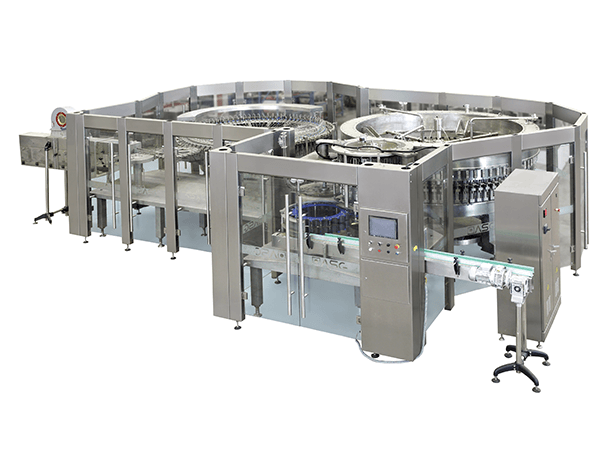

Washing head: 40

Filling head: 40

Capping head: 10

Total power:10.68kw

Weight:7000 KGS

Size: 3700x3000x2350mm

Washing head: 50

Filling head: 50

Capping head: 15

Total power:12kw

Weight:8000 KGS

Size: 4500x3300x2350mm

Washing head: 60

Filling head: 60

Capping head: 15

Total power:13kw

Weight:11000 KGS

Size: 5500x4000x2450mm

| Suitable Bottle Shape | Circular or Square | Machine Operator | 1 |

| Bottle Diameter (mm) | Φ50-Φ95 | Cap Elevator | Anti-gravity Belt Lifter |

| Bottle Height (mm) | 150-310 | Cabinet | Independent Cabinet |

| Bottle Volume | 0.2-2L | Electricals | Schneider |

| Washing | Aseptic Water | Touch Screen / PLC / Inverter | Mitsubishi or Siemens |

| Auxiliary Equipment | Water Treatment System / Bottle Blowing System / Labeling Machine / Date Printer / Packing Machine / Conveyor System | ||

1. The roller bearing is made of stainless steel, the sealing ring is made of EPDM material, and plastic is made of UMPE.

2. The gripper equipped with high-efficient spray nozzle, it can develop to any position of inwall of the bottle, and can save rinsing water. There is a cover above the spray nozzle which can prevent water spilling, and there are regulatory recycle slot and recycle pipes under the nozzles.

3. Rinsing time can be guaranteed for 4 seconds.

4. By adjusting the height of the rotary parts to adapt for different bottle height.

5. The supplying of rinsing water is controlled by solenoid valve.

1. Adopted Germany igus anti-corrosion non-maintaining bearing that can reduce the pollution of filling to the environment.

2. The filling valve opens and begins filling when it moves down and touches the bottleneck, the filling valve move up and leave the bottleneck when it finishes filling.

3. Sliding bearing is adopted Germany igus anti-corrosion non-maintaining bearing, that can reduce the pollution of filling to the environment. Rolling bearing made of stainless steel, the sealing ring is made of EPDM material, plastics is made of UMPE.

4. The motivation of the filler is derived from the driven system in the framework and passed by gear.

1. Introduce most advanced cap sealing technology called France “ZALKIN ", this improvement can reduce the defective rate of capping better and the traditional character of easy to set and adjust the torque of screwing capping head.

2. There is a cap-lock cylinder in the joint between the cap-falling guide and poking cap plate. It is realize that no feeding no cap.

3. By adjusting the height of the rotary parts to adapt for different bottle height.

4. The motivation of the screwing capper is derived from the driven system in the framework and passed by gear.

5. The main parts of the screwing capper are processed by the digital-control processing center.

> Rinsing Pump

> Back flow pump

> Main motor+ reducer

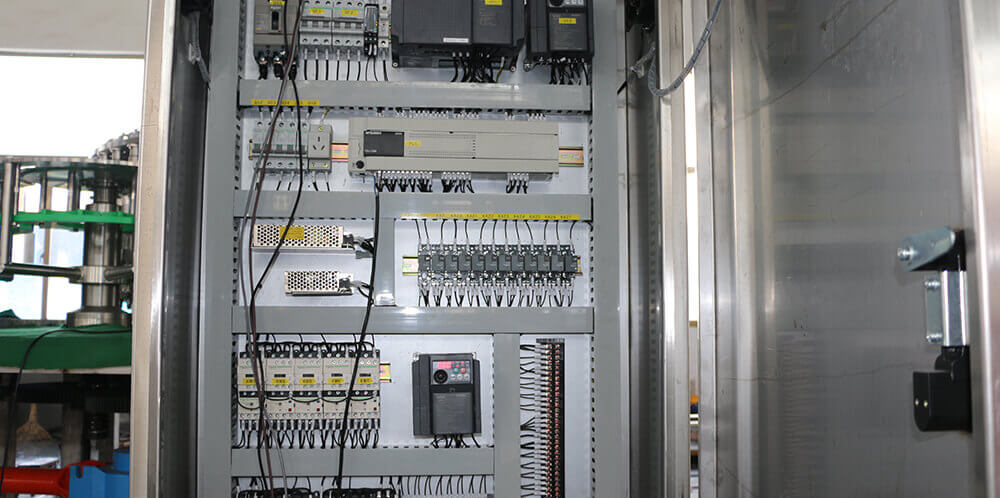

> Inverter

> PLC

> Touch screen

> Contactor

> Sensor

> Pneumatic components

CNP-CHINA

CNP-CHINA

ABB-Germany

Siemens-Germany

Siemens-Germany

Siemens-Germany

Schneider-France

BANNER-Germany

FESTO-Germany

> Sliding bearing

> Cap unscrambler motor

> Conveyor motor

> Solenoid valve

> Air cylinder

> Pressure regulation valve

> Intermediate relay

> Transformer

> Pneumatic

> a . c . contactor

Igus-Germany

FEITUO

FEITUO

Japan SMC

Japan SMC

Japan SMC

Schneider -France

China

Japan -SMC

Schneider

By continuing to use the site you agree to our privacy policy Terms and Conditions.