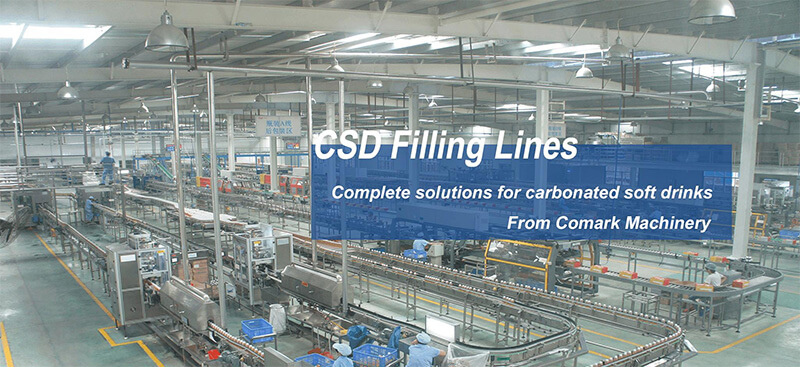

Carbonated Water Beverage Soda Soft Drink Filling Bottling Production Line The whole line include : 1> PET bottle blow molding machine 2> Water treatment system 3> Carbonated drink mixing processing system 4> Carbon dioxide mixer 5> Bottle washing filling and capping machine 6> Bottle warming tunnel 7> PVC shrink sleeve / OPP hot glue / Adhesive sticker labeling machine 8> PE film packaging machine / Carton packaging machine 9> Automatic palletizer

Carbonated Water Beverage Soda Soft Drink Filling Bottling Production Line

Application: fizzy drink,sparkling water,carbonated drinks, CSD, cola, fanta,soda water, energy drinks, kvass, beer, etc.

Containers application: PET bottle of all volumes and shapes

Filling system: isobaric filling

Production capacity: 1,000BPH–24,000BPH (500ml)

| Washing Part 1. Rinsing water distributor ensure each working position has stable water supply, as well as cut the rinsing water consumption. 2. Single fluid spray nozzle is used, rinser water is spraying in setting angle, and clean all parts inside of bottle with features complete rinsing and water saving. Water rinsing time is 4 seconds and dripping water is 2 seconds. |

Filling Part 1. Material of filling valve and tank are made from stainless steel 304L. 2. High speed and precision filling technology, filling flow rate is 35% higher than Newamstar's second generation filling technology (reaches to 200ml/s), liquid level precision ≤±2mm;. 3. Circline liquid tank, the liquid level is controlled by floating ball. |  |

| Capping Part 1. High speed and high precision capping technology and ensure capping inferior ≤0.2%. 2. Capping air tightness ≥ 99.99% 3. Adopted in constant magnetic torque capping technology. capping effect is stable and reliable. |

| Model | DCGF 14-12-5 | DCGF 18-18-6 | DCGF 24-24-8 | DCGF 32-32-8 | DCGF 40-40-10 |

| Capacity(500ml) | 2,000BPH | 4,000BPH | 8,000BPH | 10,000BPH | 16,000BPH |

| Floor area | 400 ㎡ | 600 ㎡ | 1000 ㎡ | 2000 ㎡ | 2500 ㎡ |

| Total power | 100KW | 200KW | 300KW | 450KW | 500KW |

| Operate workers | 8 | 6 | 6 | 6 | 6 |

| PET bottle blow molding machine 1. Blow moulding machine 1,000-24,000bph, and 0.2-2L / 3-5L PET bottles are available. 2. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle, etc. 3. The man-machine interface is highly automated and easy to operate. 4. The compact machine occupies a smaller area. |

Beverage pre-treatment system 1. The beverage processing system applies to bever2. product's scope hot water system, sugar dissolving system ( simple syrup system ), concentrate system, blending system (final syrup system), CIP system, extraction system, kind of storage tank / valves / pipe / fittings, UHT system (plate / tubular type), and carbo-cooler / mixer (manual / automatic). |  |

| Water treatment system 1. Pre-treatment system (water tank / multi-medium filter / active carbon filter / ion exchanger / precious filter) 2. Membrane separation system (ultrafilter / nanometer filter / RO reverse osmosis system) 3. Electrodialysis device / Sterilization system (UV device, ozone device) product water tank and so on. |

Automatic PVC shrink labeling machine 1. The machine can be used for various bottle types, such as: round bottle, flat bottle, and so on. 2. Labeling machine is controlled by PLC touch screen, all-electric eyes are using imported advanced configuration. 3. High speed, high accuracy, stable performance. |  |

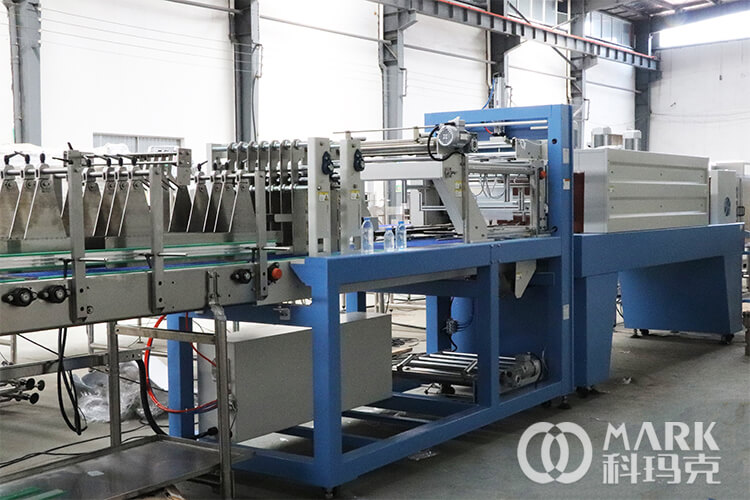

| Automatic PE film shrink wrapping machine 1. PE film shrink wrapping machine is suitable for wrapping of such products as mineral water, bottles beer, drinks etc without bottom-tray (or with bottom-tray). 2. Working with PE shrink tunnel to pack the goods perfectly. The whole producing process adopt the Germany advanced technics. |

By continuing to use the site you agree to our privacy policy Terms and Conditions.