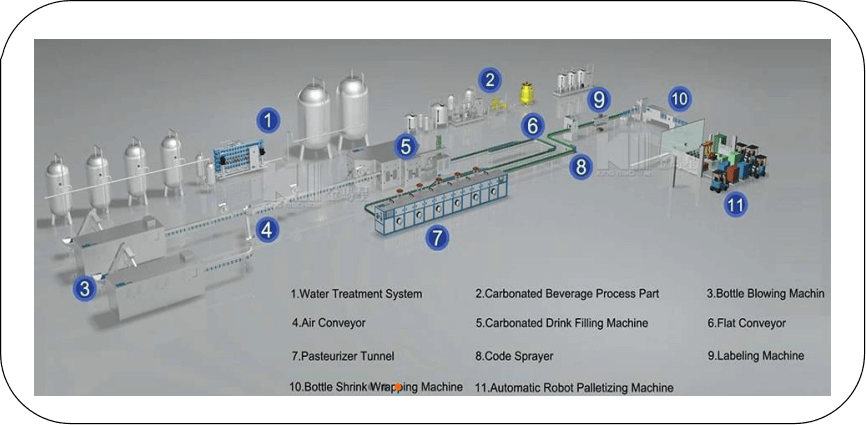

The carbonated beverage filling machine could be separated into 3 modules. The height of the bottle-out conveyor is adjustable. Bottles are conveyed to rinser, filler and capper through starwheel and conveyed out finally through the bottle-out conveyor. equipped with an alarm device for bottle block, bottle absence, cap absence and overload, the pet bottle soda filling machine meets the national food hygienic standard with high automation and easy to operate.

Application: carbonated drinks, CSD, cola, soda water, energy drinks, kvass, beer, etc.

Containers application: PET bottle of all volumes and shapes

Filling system: isobaric filling

Production capacity: 3,000BPH–18,000BPH (500ml)

Technical features of carbonated beverage filling machine

1. The air conveyor is directly connected with the bottle-in starwheel. The bottle is transferred by neck holding.

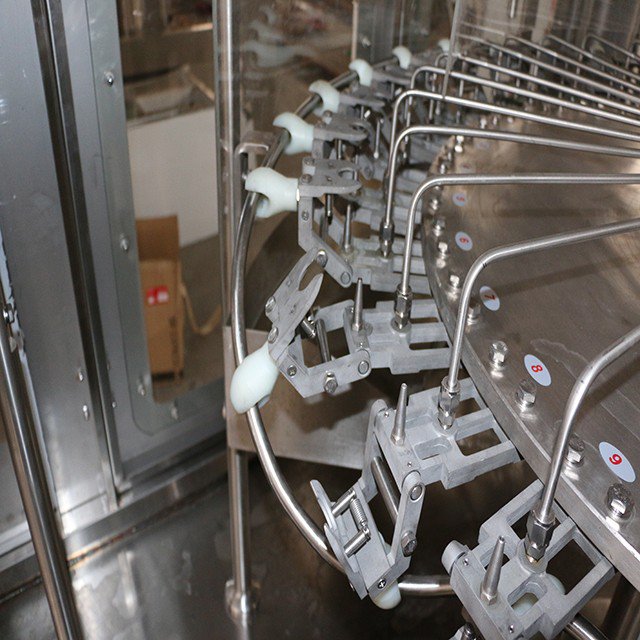

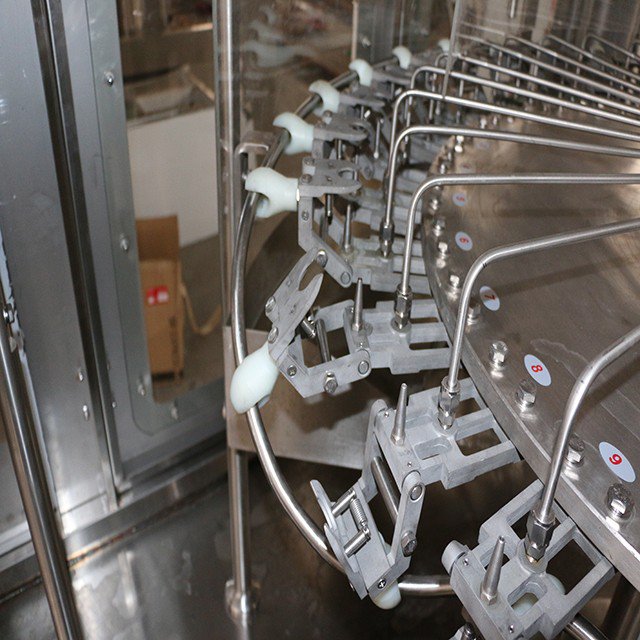

2. High-speed line adopts bottle clamps to transfer the bottle. It makes work much easier when bottle size is changed.

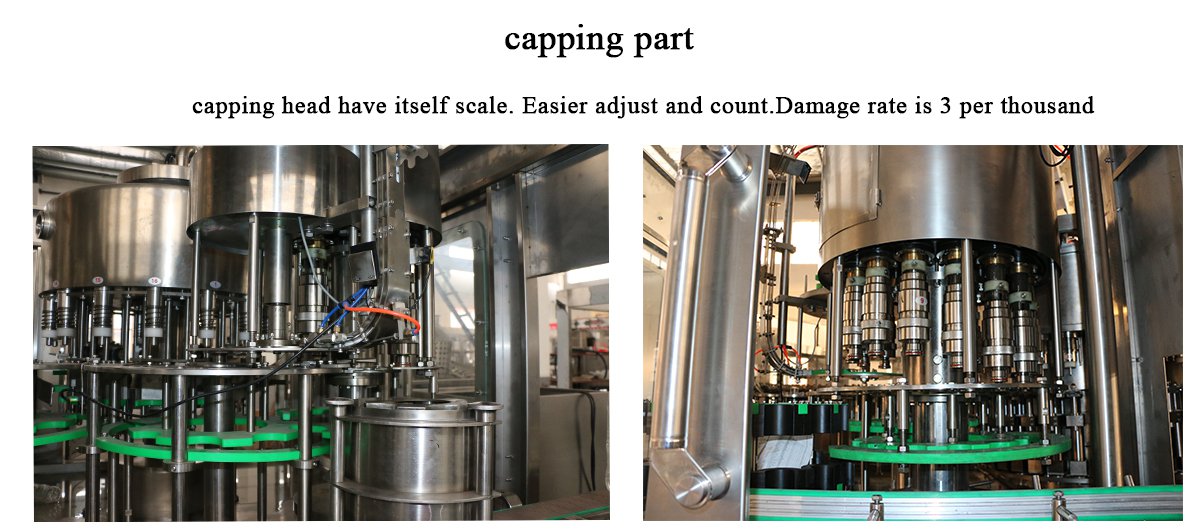

3. By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle change is easier.

4. Specially designed stainless steel bottle clamp does not contact the thread parts of the bottleneck, avoiding the second contamination.

5. The high-speed line is of ring type pressure bearing hydraulic cylinder.

6. High speed and large flow filling valve assure the high filling speed and exact fluid level.

7. Spares contact with the liquid is all of excellent stainless steel or food level plastic. The electric system is of international brand and achieves the national food sanitary standard.

8. The bottle-out starwheel is of screwdown shape. When bottle size is changed, there is no need to adjust the transferring chain’s height.l

| Model | DCGF14-12-5 | DCGF18-18-6 | DCGF24-24-8 | DCGF32-32-8 | DCGF40-40-10 | DCGF50-50-15 |

| Capacity | 2000 | 4000 | 60000 | 8000-10000 | 12000-14000 | 16000 |

Bottle Sharp | PET Round Bottle Or Square | |||||

| Bottle Dia | ∮50-∮115 | |||||

| Bottle Height | 150-320 | |||||

CAP | Plastic Screw Cap | |||||

| Power (kw) | 4.23 | 5.03 | 6.57 | 8.63 | 10.68 | 12 |

| Size (mm) | 2230*1630*2250 | 2360*1830*2250mm | 2900*2200*2250 | 3880*2200*2250 | 3700*3000*2350 | 4500*3300*2350 |

| Weight (kg) | 2200 | 2500 | 4200 | 6000 | 7000 | 9000 |

By continuing to use the site you agree to our privacy policy Terms and Conditions.