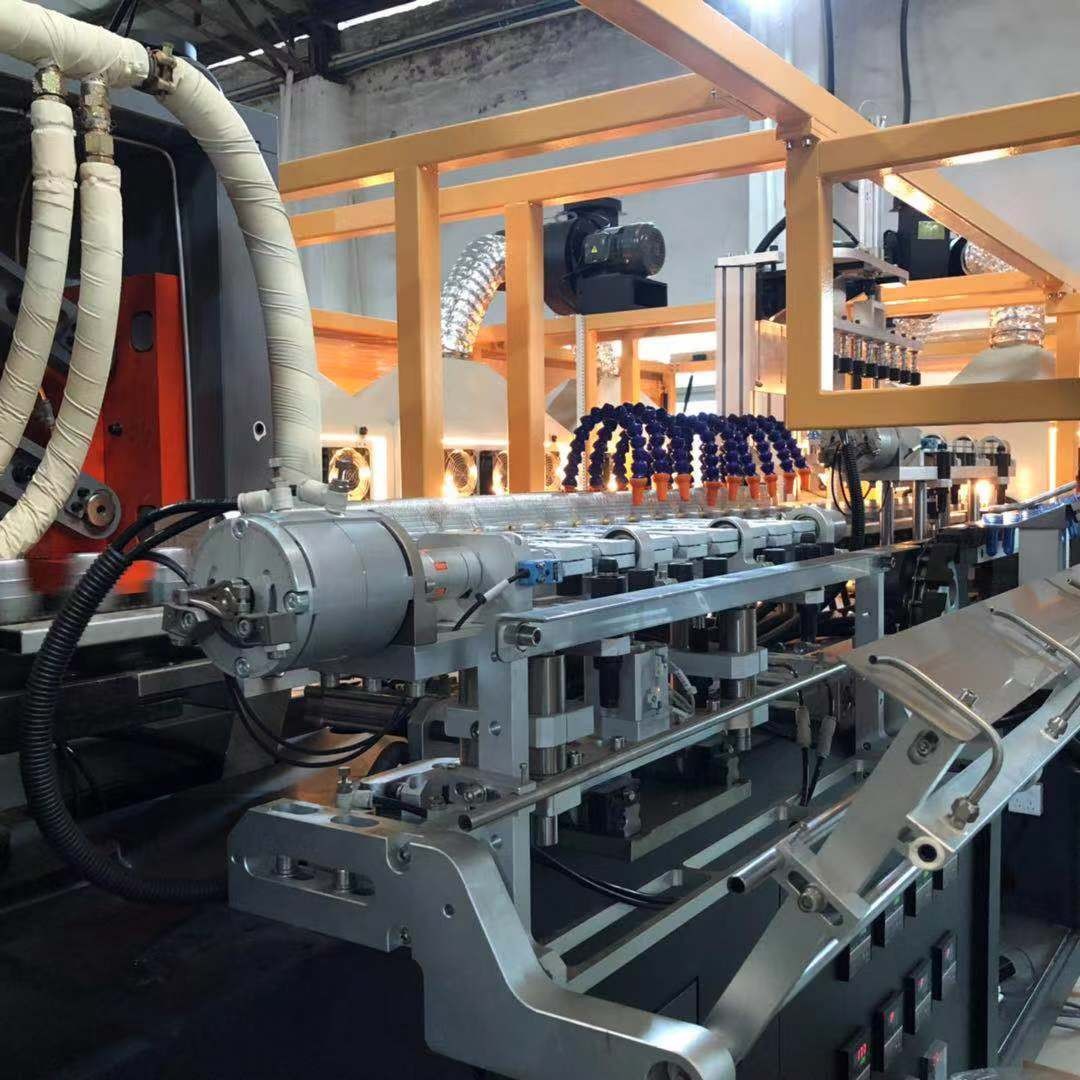

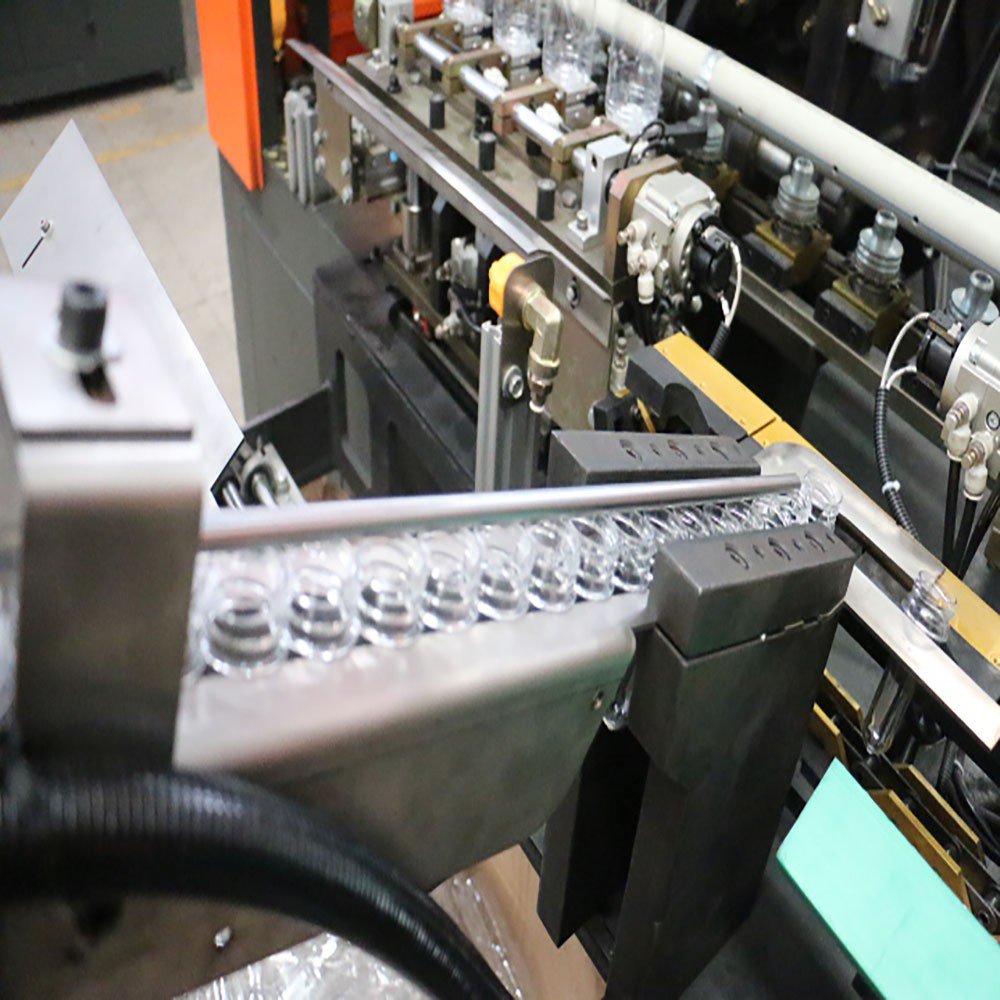

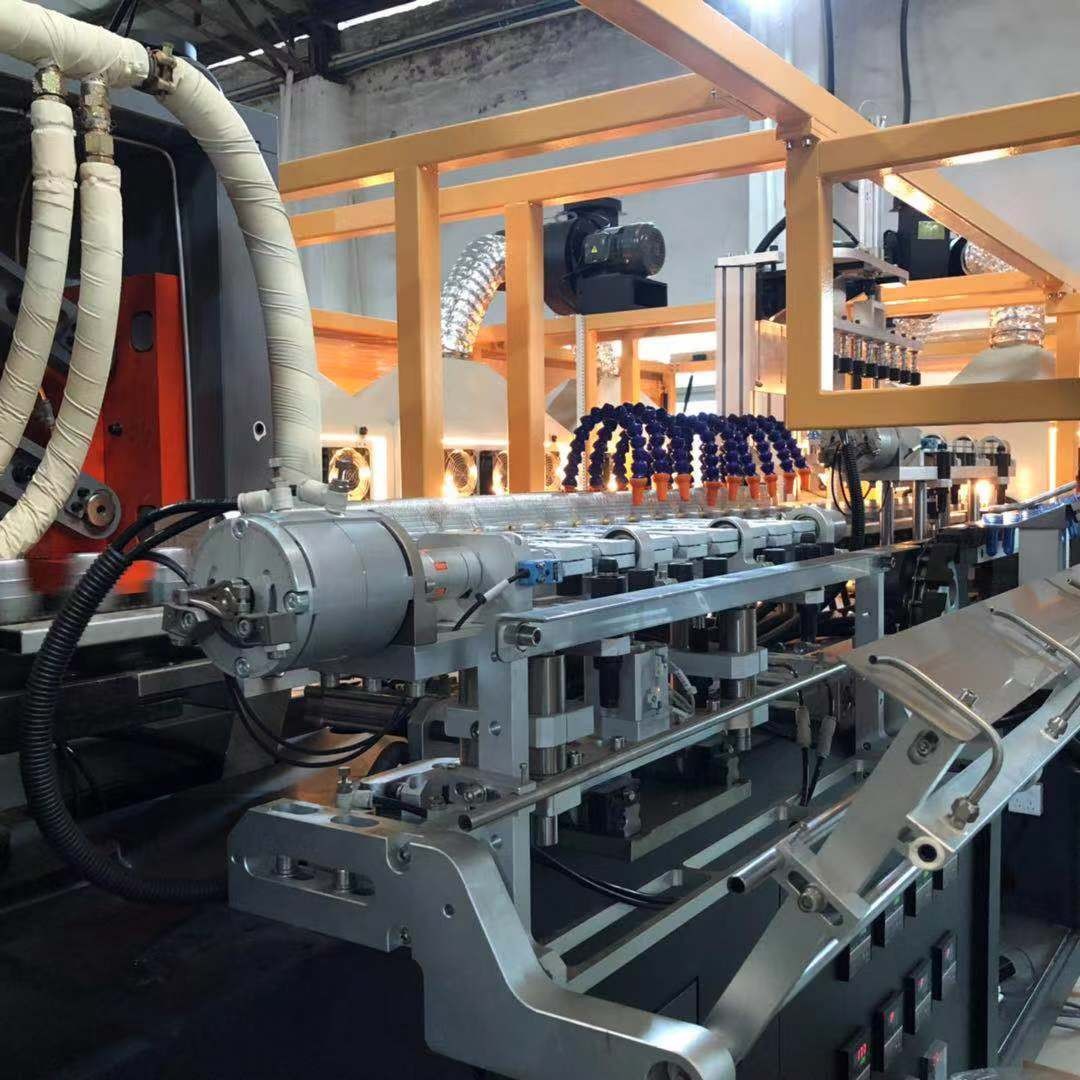

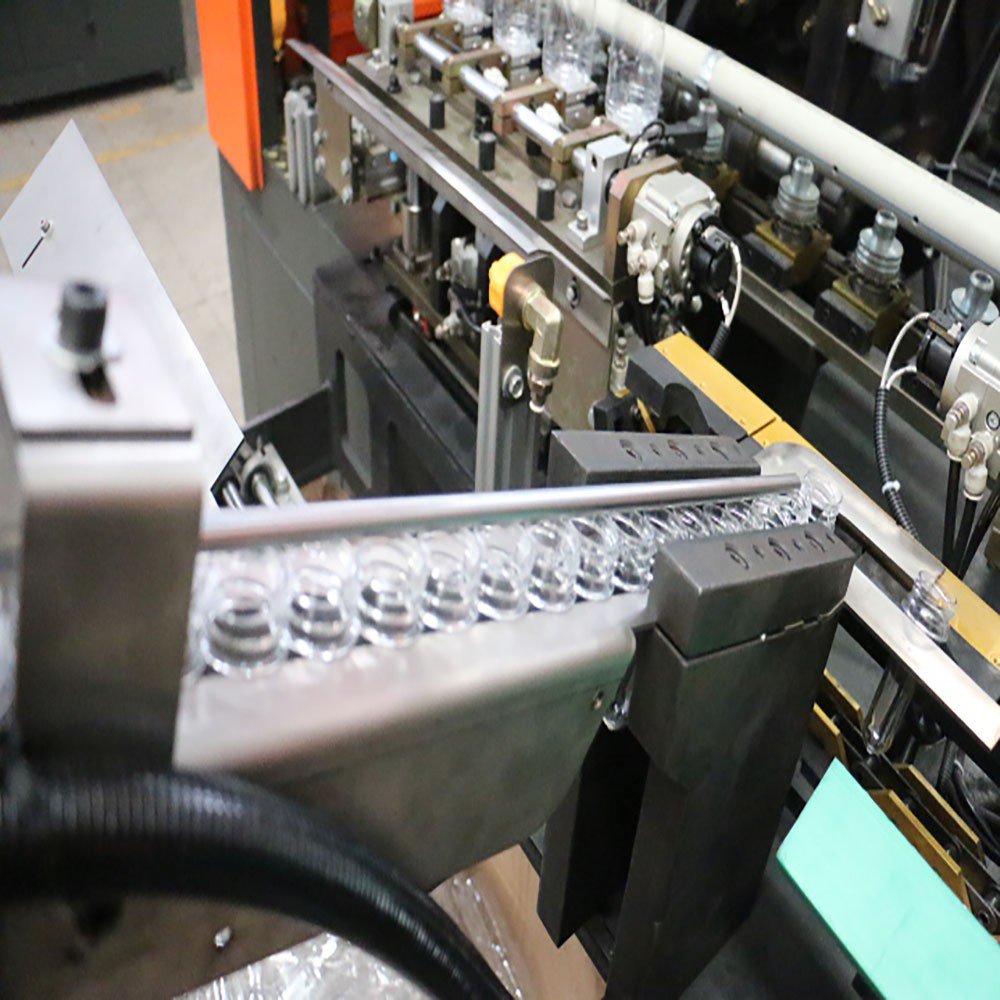

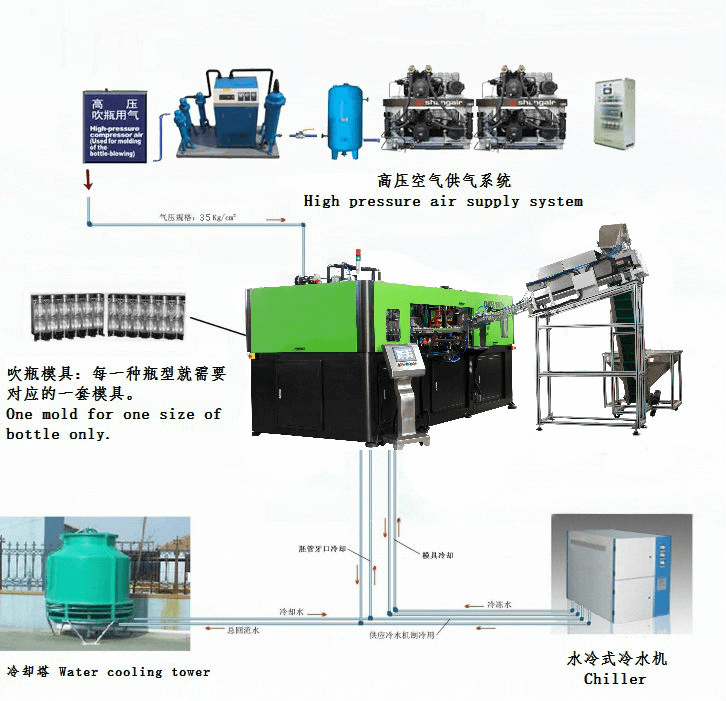

Linear automatic PET bottle injection blow molding machine, independently developed by COMARK via adopting the world’s advanced techniques, is a kind of high-speed equipment producing PET bottles by high pressure compressed gas. It has reached the top level by automatically arranging, heating and stretching preform.

Features of pet bottle blowing machine:

1. Blowing 0.5-1.5 PET common bottle.

2. Durable PLC microcomputer controlling system control time can be accurate to 0.01 seconds.

3. Special recycling installation for high-pressure air reduces energy consumption.

4. The far-infrared heater uses a way of conversion self-rotating heating and the rail revolution makes the heating even, quick and reliable.

5. Every heating lamp has an independent temperature control device, to get an ideal preform heating effect.

6. The particular pre-heater design makes perform close while heating. Change space, shorten heating tunnel and reduce energy consumption according to the bottle size while blowing.

7. Simple installation and starting.

Configuration

| Item | YCQ-2l-2 | YCQ-2l-3 | YCQ-2L-4 | |

Bottle type specification | Cavity | 2 | 3 | 4 |

| Theory output | 2400-2700 | 3500-4000 | 4500-5000 | |

| Max.volumn | 2L | 2L | 2L | |

Bottle mouth maximum overall diameter | 80mm | 28-38mm | 28-38mm | |

Bottle biggest diameter | 100mm | 100mm | 100mm | |

Power specification | Light tube quantity | 32 pcs | 32 pcs | 32 pcs |

| Light tube power | 0.75kw | 1.25kw | 1.25kw | |

| Max heating power | 24kw | 40kw | 40kw | |

Air pressure specification | Working pressure | 5-6 kg/cm2 | 5-6 kg/cm2 | 5-6 kg/cm2 |

| Temperature range | 10 degree | 10 degree | 10 degree | |

| Consumption | 5000 kcat/hr | 8000 kcat/hr | 8000 kcat/hr | |

Machine specification | Size of machine | 2.25*1.6*1.7 | 4.0*1.6*1.9 | 4.5*1.6*1.9 |

| Weight of machine | 2.5 ton | 3 ton | 3.5 ton |

By continuing to use the site you agree to our privacy policy Terms and Conditions.