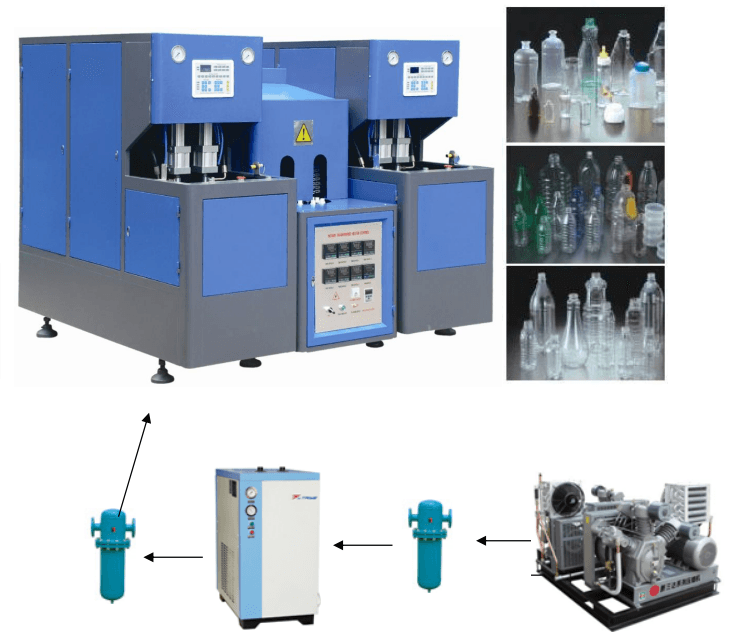

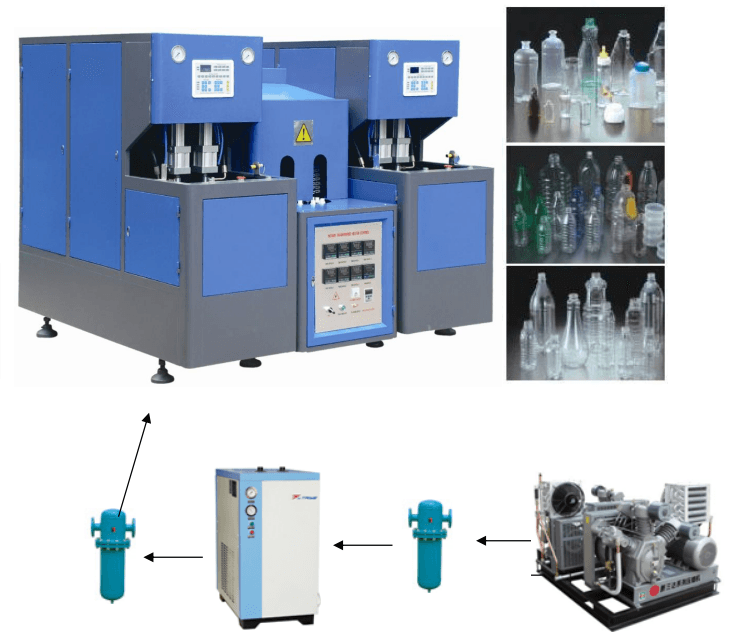

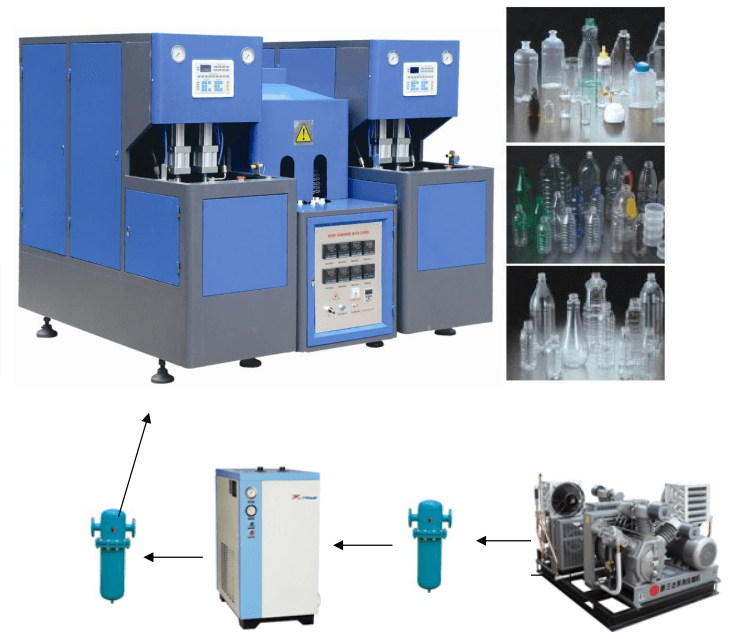

Semi-auto bottle making machine bottle blowing machine used for blow PET plastic bottles.Simple operation and high control precision.

Products Description:

1. Double crank arm for mold locking reaches high mold-locking strength and flexible action.

2.Use PLC for control (time relay control optional), easy repair, low cost, with the time controllable accurately in 0.01s.

3. The gas circuit consists of moving and blowing so as to satisfy the different air demands of them.

4. The far-infrared heater uses a way of conversion self-rotating heating and the rail revolution makes the heating even, quick and reliable.

5. Every heating lamp has an independent temperature control device, to get an ideal preform heating effect.

6. The direction of the heating lamp is adjustable upon different preforms.

7. Only need two operators, do not need special training. Simple installing and starting.

Main Parameters:

Model | CO-2L | |

Container | Product material | PET |

Volume | 0.1L-2L | |

Theoretical output | 1600-2000PCS/H | |

Preform length | 15mm-350mm | |

Preform inner diameter | φ5mm-38mm | |

Molding | Max.mould plate Dimension (LxW) | 350x380mm |

Max.mould thickness | 180mm | |

Clamping force | 45KN | |

Mould opening stroke | 160mm | |

Machine size & weight | Main machine (LxWxH) | 160x60x161cm |

Main machine weight | 500Kg | |

Heater (L x W x H) | 187x63x145cm | |

Heater weight | 250Kg | |

Power | 17.5kw | |

By continuing to use the site you agree to our privacy policy Terms and Conditions.