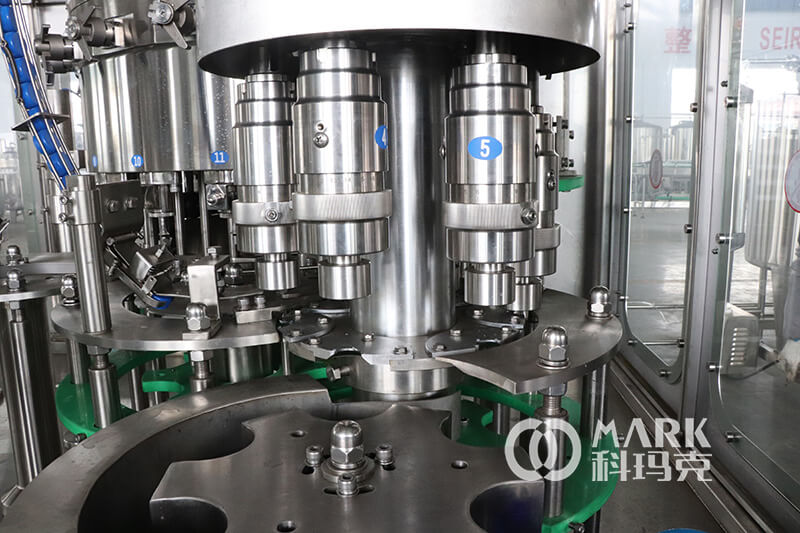

4000BPH Full Automatic CO2 Sparkling Water Filling Machine could be separated into 3 modules. The height of the bottle-out conveyor is adjustable.bottles are conveyed to rinser, filler and capper through starwheel and conveyed out finally through the bottle-out conveyor. Equipped with alarm device for bottle block, bottle absence, cap absence and overload. The machine meets the national food hygienic standard with high automation and easy to operate.

Application: sparkling water,carbonated drinks, CSD, cola, fenta,soda water, energy drinks, kvass, beer, etc.

Containers application: PET bottle of all volumes and shapes

Filling system: isobaric filling

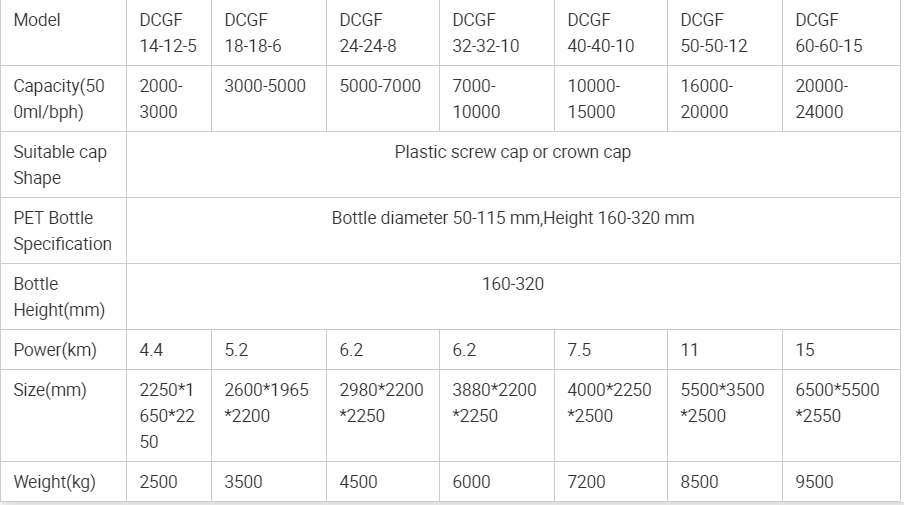

Production capacity: 2,000BPH–24,000BPH (500ml)

4000BPH Full Automatic CO2 Sparkling Water Filling Machine

1. The high-speed line adopts bottle clamps to transfer the bottle. It makes work much easier when the bottle size is changed.

2. By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle change is easier.

3. High speed and large flow filling valve assure the high filling speed and exact fluid level.

4. Spares contact with the liquid is all of excellent stainless steel or food level plastic. The electric system is of international brand and achieves the national food sanitary standard.

Bottle infeed

Washing Part

1. Rinsing water distributor ensure each working position has stable water supply, as well as cut the rinsing water consumption.

2. Single fluid spray nozzle is used, rinser water is spraying in setting angle, and clean all parts inside of bottle with features complete rinsing and water saving. Water rinsing time is 4 seconds and dripping water is 2 seconds.

Filling Part

1. Material of filling valve and tank are made from stainless steel 304L.

2. High speed and precision filling technology, filling flow rate is 35% higher than Newamstar's second generation filling technology (reaches to 200ml/s), liquid level precision ≤±2mm;.

3. Circline liquid tank, the liquid level is controlled by floating ball.

Capping Part

1. High speed and high precision capping technology and ensure capping inferior ≤0.2%.

2. Capping air tightness ≥ 99.99%

3. Adopted in constant magnetic torque capping technology. capping effect is stable and reliable.

Blow Molding Machine

Automatic PET Bottle Blow Molding Machine is suitable for producing PET plastic containers and bottles in all shapes.

Water Treatment System

source water tank--water pump--silica sand filter-- active carbon filter-- sodium-- ion exchanger-- precision filter--reverse osmosis system-- uv sterilizer --Ozone sterilizer --pure water tank

Used for pure water, mineral water and other bottled water,water for food and beverage production.

Drink mixer

Carbonated beverage mixing system structure reasonable, mix precision is high, CO2 mixes fully, has two times of cooling, two carbonation merits. Mainly is suitable for kinds of carbonated drink's mix processing, also may use in the paste drink, the fermentation drink and so on other soft drinks' mix processing.

Blow Dryer

This machine installed after the filling machine. This machine is used to removing the water outside the bottle surface, the blowing capacity can be adjusted through the button.

Laser Printer Machine

1. Good beam quality, TEM00 single mode output, beam diameter 10mm after collimation, M2<1.3, beam divergence Angle 0.24mrad;

2. Main-oscillation power amplification technology without maintenance and pulse generation technology of seed light source;High reliability, average no fault.

Opp Hot Glue Labeling Machine

This hot melt glue plastic bottle label applicator is widely suitable for different material of container and label. The label cost is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is the most economical models in cost to make mass production and intergrated operating.

Automatic PE film shrink wrapping machine

PE film Shrink wrapping machine is suitable for wrapping of such products as mineral water, bottles beer, drinks etc without bottom-tray (or with bottom-tray). Working with PE shrink tunnel to pack the goods perfectly. The whole producing process adopt the Germany advanced technics.

By continuing to use the site you agree to our privacy policy Terms and Conditions.