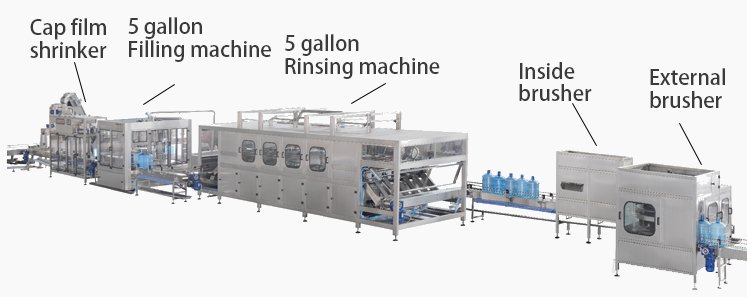

300 Bph 5 Gallon Water Bottling Machine With PET Barrel Bottle integrate rinsing , filling and capping , suitable for filling the pure water or the mineral water in 3 or 5 gallons . The filling speed ranges from 100BPH to 1500BPH , rinser-filler-capper monoblock , automatic loading machine , bottle outside washer , bottle inside washer , decapper , heating shrink tunnel , conveyor system , complete line control system .

100-150 BPH 5 Gallon 20L Complete Water Filling Machine Production Line With PET Barrel Bottle consists of washing, filling and capping, which is applied to the production of 3 or 5 gallon purified water and mineral water. The capacity can meet different production requirements from 100 to 2000 BPH.

The entire line includes the following optional equipment: Cap pulling machine, leak detection machine, brushing machine, automatic barrel loading device, washing / filling / capping three-in-one machine, barrel neck thermal machine, bagging machine, palletizer and etc.

3-5 gallon barrel water filling machine

1. Adopt food grade SUS304 stainless steel material, compact structure, reasonable design, small footprint, production capacity from 100-3000b/h all can be customized;

2. PLC control, touch screen human-computer interaction interface, easy to operate, easy to maintain; The whole line output can be adjusted and has good compatibility and expansibility.

3. Perfect to meet customer needs, it is 3-5 gallon barrel water filling manufacturers ideal production and processing equipment!

>>12 steps washing procedure: 1. pre-washing, 2&3. alkali washing, 4.dropping 5&6 recycle water washing 7. dropping 8&9 disinfect water washing 10&11 finish water washing 12.dropping

>>All 304 stainless steel rinser heads, water spray style inject design, more save water consumption & more clean

>>304 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

>>304 stainless steel Rinsing pumps

>> All food grade SUS304/316 design

>> Effectively clean bottle and save water

>> Resting waiting for water drops

>>High precision filling nozzle, PLC variable signal control, ensure high filling precision & filling smoothly & steadily

>>All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean

>> Filling valve, guide rail, elevating device, etc.

>> Gravity filling type (No touch filling type)

>> Filling volume adjustable

>> All food grade SUS304/316 design, harmless for beverages and easy to clean

>>No bottle no filling

>>Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

>>All 304stainless steel construction

>> Cap unscrambler, cap drop rail and capper

>> Minimum bottle crash during capping

>> No bottle no capping

By continuing to use the site you agree to our privacy policy Terms and Conditions.