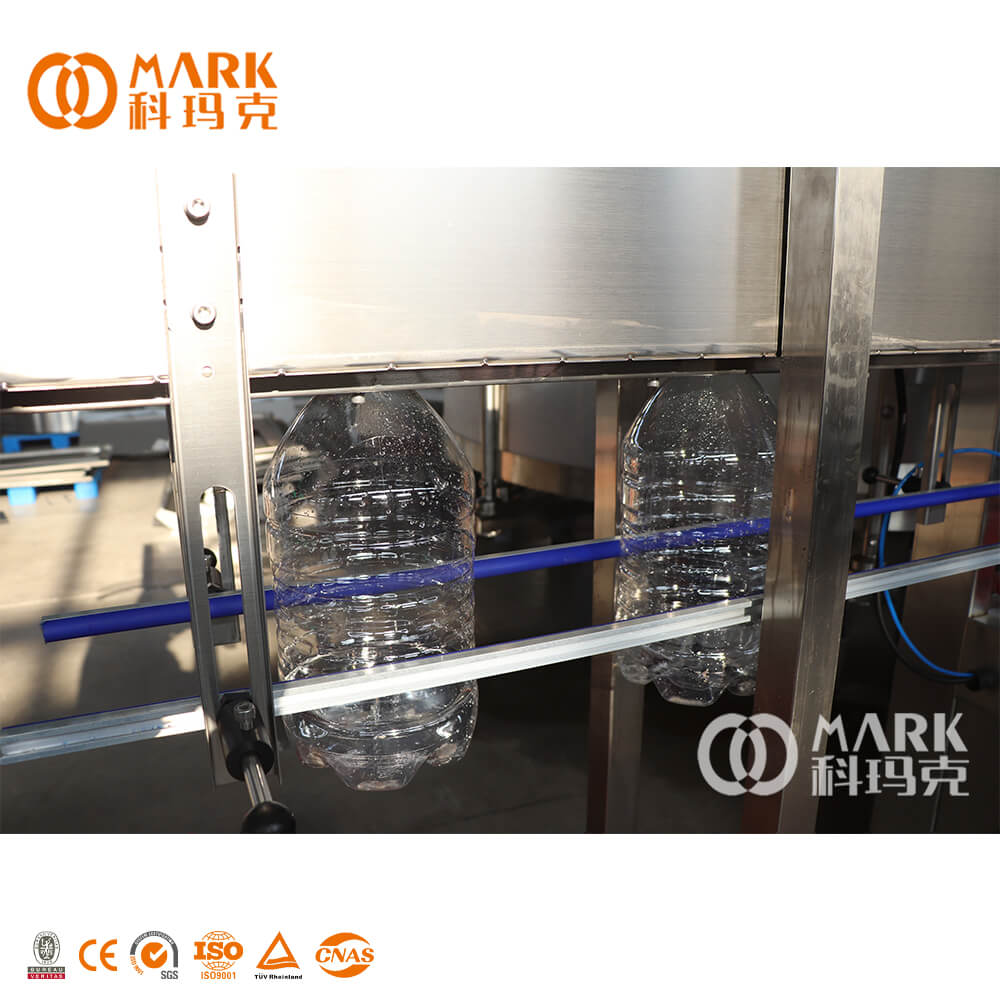

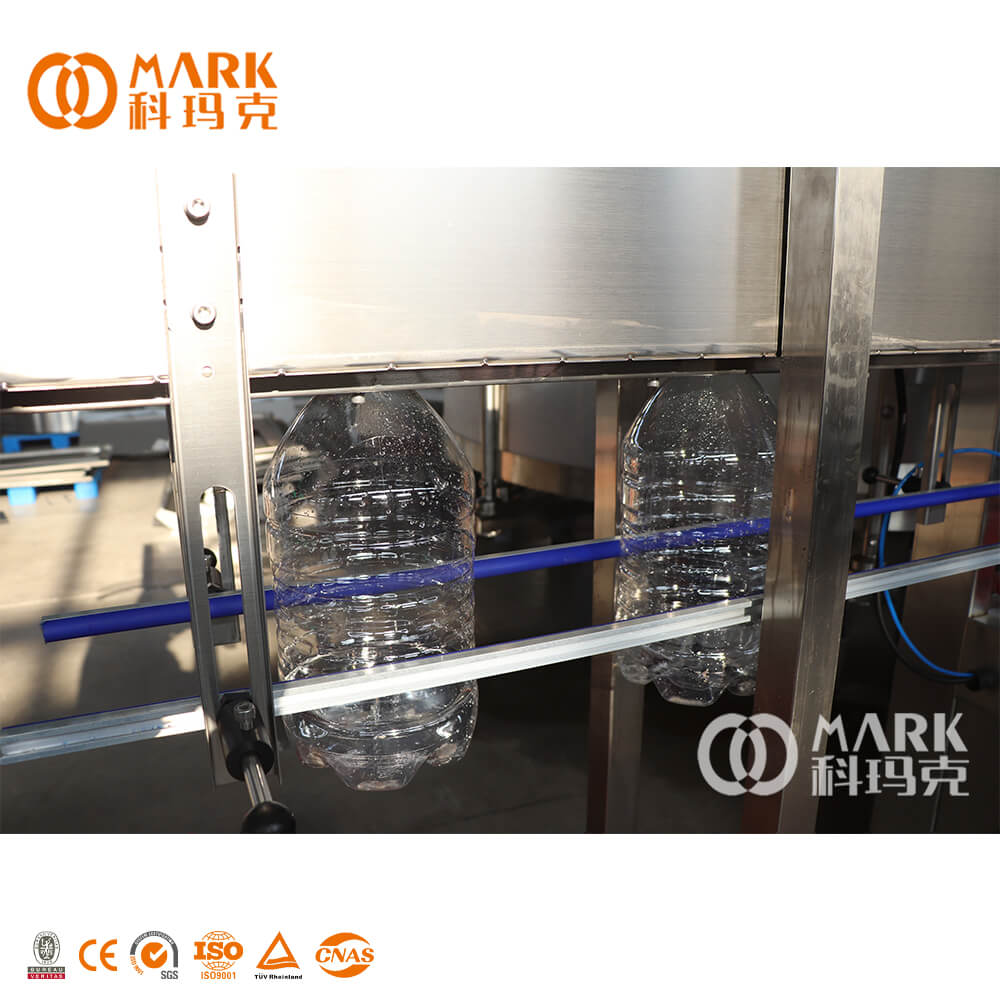

This water filling machine is specially designed by 5L ,6L,10L bottle . All parts of this machine is made of high quality stainless steel materials, it cannot cause rust to influence the filling beverage, it not only reach the standard of sanitation, but also prolong its using life.

1,000BPH Automatic 3-10L Bottle Water Filling Making Machine

New 5 liters water filling machine is used to fill pure water, mineral water and other non-carbonated beverage.

All the machine part which contact with liquid is high quality stainless steel 304. The relative fittings are from international famous brand.

This water washing filling capping machine is comprised of rinsing, filling and capping system.

This machine owns the reasonable, stable and safe design. Under the condition that the bottle neck size is the same, only the output star wheel needs to be changed if bottles are different. It improves the efficiency a lot.

1.3-10L washing filling capping machine

A) Washing part of Water Filling Machine:

The bottle enters into the rinsing part of three-in-one machine through wide conveyor belt.

The grippers take the bottles from the inlet star-wheel while they are still driven by the star-wheel, thus guaranteeing a safe grip. After the gripping, the bottle is turned upside down with 180 degree and cantred above a spraying nozzle which directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to an upright position again

B) Filling Part of Water Filling Machine :

High precision filling nozzle, PLC variable signal control, ensure high filling precision. Gravity filling, filling smoothly

High speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic.

C) Capping part of Water Filling Machine:

Rotative capping turret, suitable to the application of screw plastic caps on PET bottles

The fixed part consists of the cap hopper, the cap feeder with relevant motor and the cam actuating the capping heads. The heads are raised and lowered by the action of a follower that is riding on a shaped cam.

2.Water treatment system

The Processing Of Water Treatment System

* Raw water tank/Raw water pump

* Silica sand filter/Active carbon filter/Sodium ion ex-changer/Precision filter

* Ultrafilter / Nanometer filter / RO reverse osmosis system

* Electrodialysis device / Sterilization system (UV device, ozone device) product water tank

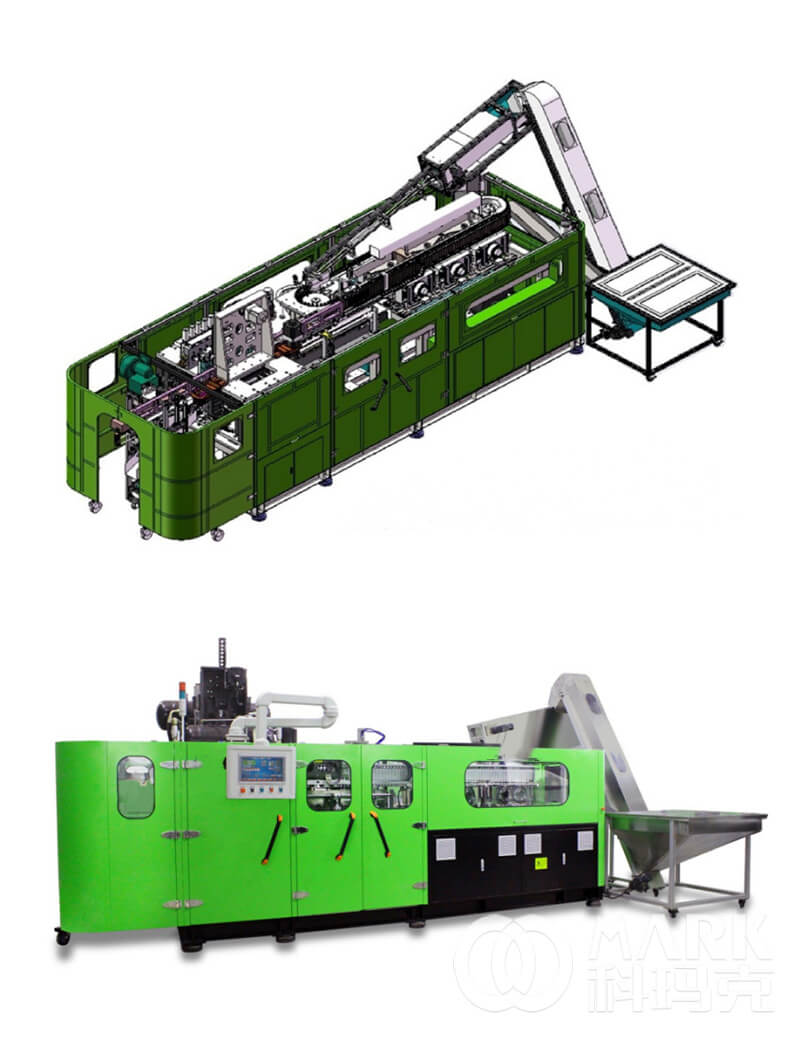

3.blowing machine

R series linear full electric PET bottle blow molding machine is a high speed automatic PET blower designed and developed with the most advanced bottle blowing technology at present, the advantages of which can be described as speedy, stable, simple, general purposed and environmental safe. It is mainly applicable in blow molding PET containers for water, beverage, juice, etc. The machine yields abundantly with high efficiency. The capacity of each cavity has been increased to 1200~1000bph when the bottle size is equal to or less than 5L respectively, which can meet the high-end customer's requirements. Equipped with preform auto loading system, the machine works fully automatically with consistent performance and high speed, without any operator's interference during the whole processes. Accordingly, chance of contamination can be reduced manifestly, which assures the quality of products.

4.bottle dryer

Adopt high-pressure blower, discharge the air from a small gap, to blow off the water on the bottle body. The gap is laid incline, which can make the whole body touch the air. It consist of high-pressure blower, blowpipe, frame, control device, surge tank etc.

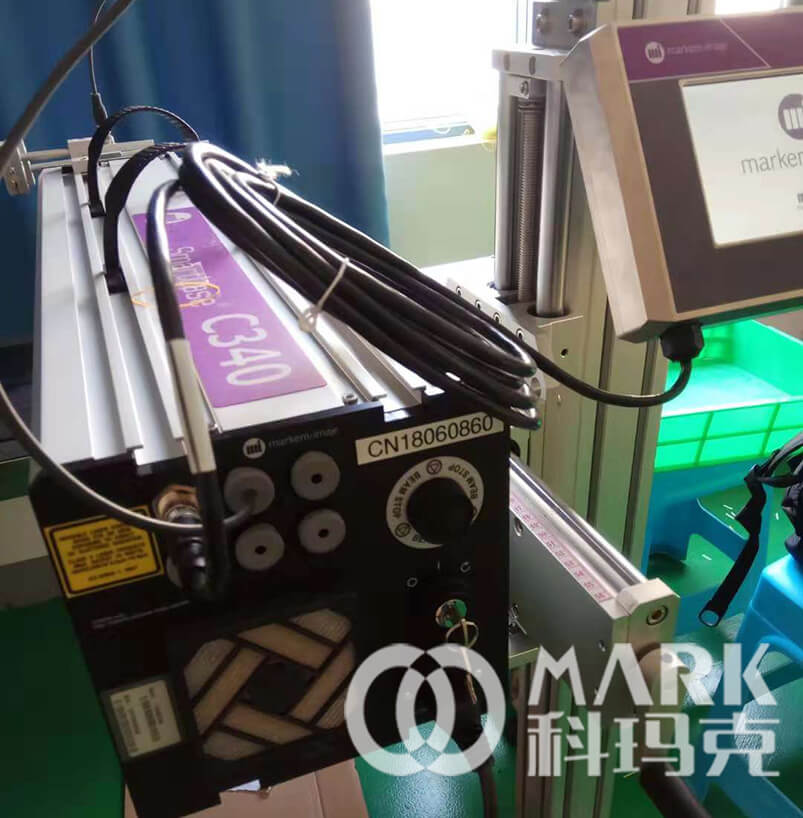

5.laser printer machine

• Character height: from 1 to 120 mm

• Wide selection of languages: English, French, Spanish, German, Italian, Portuguese, Brazilian, Chinese, Korean, Japanese,

• Main-oscillation power amplification technology without maintenance and pulse generation technology of seed light source;High reliability, average no fault

6.Labeling machine

The material of label are using environmentally material of OPP films . It can be automatically oxidative decomposition and reduce production costs by more than 30 percent . Labeling machine is control by PLC touch screen , all electric eye are using imported advanced configuration . This labeling machine with high speed , high accuracy , stable performance , easy to operate and look elegant appearance .

7.warpping machine

• Classic shape, beautiful, novel structure, unique, easy operation and maintenance. The use of pneumatic expansion support film roll, electronic sensor film delivery, sending film stable, fast and convenient for membrane.

• unique “bottles vibration”(patented technology) can make the product smoothly separated, avoiding the phenomenon of bottle squeezing

• Shrinkage chamber using the newly developed open structure outside to facilitate maintenance; thick insulation layer, energy-saving effect, high temperature control accuracy.

8.film pallet stretch wrapping machine

• PLC programmable control, winding program optional, various parameters adjustable,Photoelectric switch automatically senses the height of goods

• Pre stretching automatic film feeding mechanism

• Slow start, slow stop and automatic reset of rotary table

Q:If we purchase machines, what can you provide for us?

A1:We can provide whole solutions.We have professional engineer who analysis production demand based on customer market demand and customer budget .

A2:We have the bottle shape design according to customer inquire. We also can provide the machines layout for you according your factory figure plan.

A3:We will send our professional engineer to your factory as soon as you get all your machines ready, for installation, testing and teaching your technicians how to run the machines.

Q:Do you have any reference project?

A:We have reference project in most countries, and you can visit their factories if we get the permission of the customer. And we have made video of every machine and uploaded them to Youtube.I can share with you.

Q:When can I get my machine after I paid?

A:We will deliver the machines on time as the date we agreed both side. Normally production time is around 35-75 days. The exact time depends on what kinds of machine you ordered. The shipping time is based on your destination port.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you. You can come to China.Check it!

Q:What's your guarantee or the warranty of the quality if we buy your machines?

A:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

By continuing to use the site you agree to our privacy policy Terms and Conditions.