1.It is specially used for filling 3 gallon to 5 gallon bottled water. 2. The machine is designed for bottles such as PVC. PE. PET etc. It can be used for different shapes of bottles. 3. The machine line with stainless steel rinse nozzles, pressure filling valve, screw capper, hot steam film shrinkage machine for top quality line. 4. Filling time is controlled by the PLC. 5. The machine adopts high quality stainless steel frame(No. Z304).

Whole 5 Gallon Pure Drinking Water Bottling Production Line

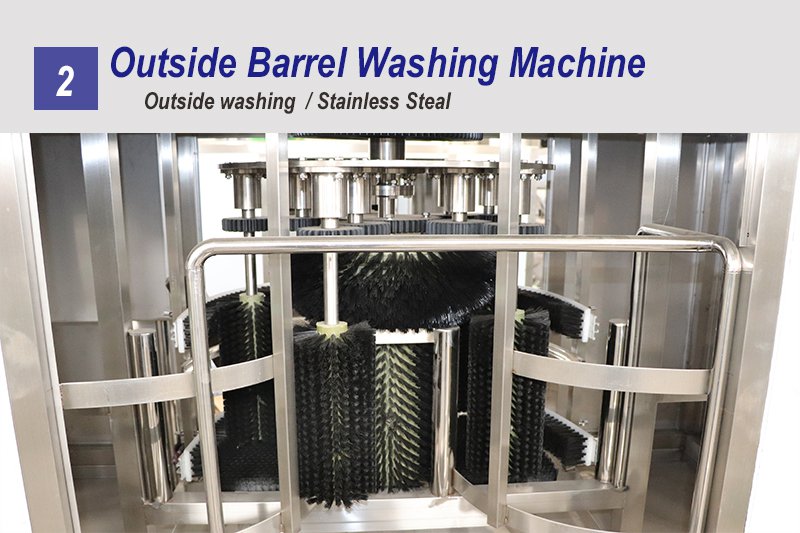

Barreled water production line is specially used for the production of 3 gallon, 5 gallon barreled drinking water.The machine integrates washing, filling and capping functions.It is an ideal equipment for mineral water, distilled water and purified water production.The machine adopts high quality stainless steel, corrosion resistance, easy to clean.The main electrical components are SIEMENS and OMRON products.Airway system adopts imported AIRTAC famous brand products.The machine has the advantages of compact structure, small workshop area, high efficiency, stable and reliable, and high degree of automation.Operators only need two people, is a trinity of mechanical and electrical automatic barrel equipment

Technical Parameters

| Washing part 1.In order to achieve the purpose of washing and sterilizing, barrel washer adopts multiple liquid injections washing and disinfectant spray, and washing solution can be used circularly. 2. 304/316 Stainless steel high precision filling nozzle. 3.All 304/316 stainless steel contact parts & liquid tank |

Filling parts 1.Uploading and dropping barrels changed from 45 degree to translatory which is more stable. 2.Nozzle can insert into 10-15cm of the barrel in order to rinse little impurities down. Rinsing pump is separately controlled by different magnetic valves. Pump only work when there is barrel on that. |  |

| Capping parts 1.Liquid level difference is controlled in 1cm. 2.Machine is equipped with Cap Sterilization system, which is 1.2m. The system make products more clean and safe by using sterilization and finished water. |

| Model | QGF-150 | QGF-300 | QGF-450 | QGF-600 | QGF-900 | QGF-1200 |

| Capacity(BPH) | 150 | 300 | 450 | 600 | 900 | 1200 |

| Filling heads | 1 | 2 | 3 | 4 | 5 | 6 |

| Power supply(KW) | 1.38 | 3.8 | 5.6 | 7.5 | 9.75 | 12 |

| Size(mm) | 3700*1300*1600 | 4060*1860*1600 | 5000*2600*2200 | 5400*2600*2200 | 8500*6000*2500 | 9000*6500*2800 |

| Weight(KG) | 680 | 1500 | 2100 | 3000 | 3500 | 4000 |

Related Products

By continuing to use the site you agree to our privacy policy Terms and Conditions.