Application: water and beverage bottles etc. Suitable for: different size and shapes Pet plastic bottles(0.3-2L). Automation:Semi-automatic Blowing system: extrusion blow. Production capacity: 2,000BPH (500ml)

Semi Automatic PET Plastic Bottle Blow Molding Machine

1. It is controlled by imported electrical components, which has the advantages of accurate performance, strong stability and simple operation

2. It has the advantages of low investment, high efficiency, low power consumption, LED lights make the operation very convenient for employees, simple maintenance, and anti-pinch probes to improve the safety performance of the equipment

3. The use of famous brand pneumatic components and solenoid valves have high sensitivity, fast switching speed, low failure rate, safe and reliable operation, high control accuracy and fast response

|  |  |

|  |  |

Machine type: Two sets of blowing machine + one set of preform heater | Bottle material: PET Bottle type: 200 ml-2000 ml | Bottle design: According to customer sample, also we can help to design |

| Item | Specification | |

| Model | CO-2L | |

| Container | Product material | PET |

| Volume | 0.2L-2L | |

| Really output | 1200-1600PCS/H | |

| Preform length | 15mm-350mm | |

| Preform inner diameter | φ5mm-38mm | |

| Moulding | Max.mould plate Dimenstion(L * W) | 350*380mm |

| Max.mould thickness | 180mm | |

| Clamping force | 45KN | |

| Mould opening stroke | 160mm | |

| Machine size and weight | Main machine (L * W * H) | 160*60*161cm |

Main machine weight | 500Kg | |

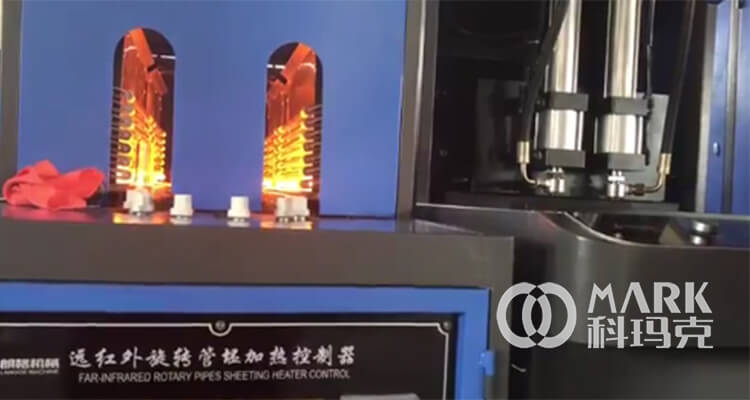

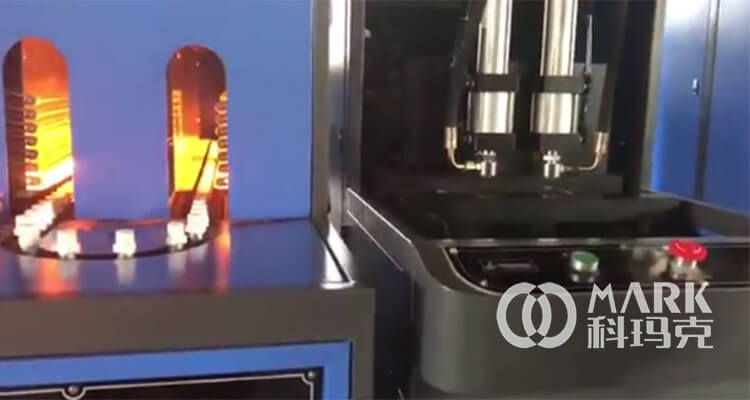

Heater (L * W * H) | 187*63*145cm | |

Heater weight | 250Kg | |

Power | 17.5kw | |

By continuing to use the site you agree to our privacy policy Terms and Conditions.