The standard type of RCGF series hot filling machine is “3-in-1”, aiming at special production condition, one disinfectant rinser can be increased to be 4-in-1 monobloc. The system gives full consideration for beverage’s characteristics (e.g. it is easy to have foaming for tea beverage and mixed juice.) and main technical requirement of hot filling.

Fruit Apple Juice Hot Filling Bottling Equipment Production Line

Application: juice, milk, vitamin drinks, functional beverage with particles, flesh, pulp, fruit pieces, etc.

Suitable for: PET bottles with all volumes and shapes

Filling system: gravity filling

Production capacity: 2,000BPH–24,000BPH (500ml)

Washing head

1. The rotary wheel is a fully stainless steel welded structure.

2. All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

3. The rinser is driven by driving system positioned inside machine frame via gear transmission.

Filling head

1. Rotary wheel fully made of stainless steel SUS 304.

2. Filling valves are made of SUS316.

3. Filling valves are reasonably structured with accurate filling.

4. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

Capping head

1. Efficient centrifugal cap sorting method, with less cap abrasion.

2. Magnetic constant torque capping head, the capping effect is stable and reliable, and the capping defective rate is less than 0.2%

3. No bottle, no capping

4. High precision, stable.

5. All 304stainless steel construction

Cap sterilization

machine parameter

| Model | RCGF14-12-5 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-8 | RCGF40-40-10 | RCGF50-50-15 |

| Capacity | 3000-4000 | 4000-6000 | 8000-10000 | 12000-14000 | 16000-18000 | 20000-24000 |

| Height | 150-320 | |||||

CAP | Plastic Screw Cap | |||||

Power (kw) | 4.23 | 5.03 | 6.57 | 8.63 | 10.68 | 12 |

Size (mm) | 2230*1630*2250 | 2360*1830*2250 | 2900*2200*2250 | 3880*2200*2250 | 3700*3000*2350 | 4500*3300*2350 |

Weight (kg) | 2200 | 2500 | 4200 | 6000 | 7000 | 9000 |

configuration

1. Material of filling valve: Stainless steel 316L available

2. Material of rotary tray and machine platform of rinser and filler: Stainless steel 304.

3. Main motor: ABB/SEW (Germany)

4. Sliding bearing: Igus (Germany)

5. Frequency inverter: MITSUBISHI (Japan)

6. Touch screen: DIGITAL (Japan).

7. PLC: MITSUBISH (Japan)

8. Pneumatic components: FESTO (Germany)

9. Seals: Busak+Shamban (USA)

10. Photocell switch: BANER (USA).

11. Proximity switch: TURCK (Germany).

| PET bottle blow molding machine 1. Blow moulding machine 1,000-24,000bph, and 0.2-2L / 3-5L PET bottles are available. 2. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle, etc. 3. The man-machine interface is highly automated and easy to operate. 4. The compact machine occupies a smaller area. |

Beverage pre-treatment system <1> The beverage processing system applies to beverage processing for hot filling line <2> product's scope hot water system, sugar dissolving system ( simple syrup system ), concentrate system, blending system (final syrup system), CIP system, extraction system, kind of storage tank / valves / pipe / fittings, UHT system (plate / tubular type), and carbo-cooler / mixer (manual / automatic). |  |

| Water treatment system 1. Pre-treatment system (water tank / multi-medium filter / active carbon filter / ion exchanger / precious filter) 2. Membrane separation system (ultrafilter / nanometer filter / RO reverse osmosis system) 3. Electrodialysis device / Sterilization system (UV device, ozone device) product water tank and so on. |

Automatic PVC shrink labeling machine 1. The machine can be used for various bottle types, such as: round bottle, flat bottle, and so on. 2. Labeling machine is controlled by PLC touch screen, all-electric eyes are using imported advanced configuration. 3. High speed, high accuracy, stable performance. |  |

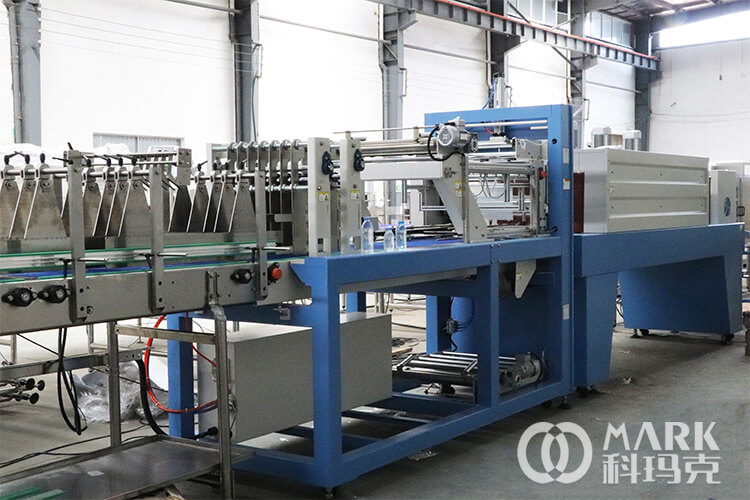

| Automatic PE film shrink wrapping machine 1. PE film shrink wrapping machine is suitable for wrapping of such products as mineral water, bottles beer, drinks etc without bottom-tray (or with bottom-tray). 2. Working with PE shrink tunnel to pack the goods perfectly. The whole producing process adopt the Germany advanced technics. |

By continuing to use the site you agree to our privacy policy Terms and Conditions.