Tremendously raise the efficiency of cup feeding before sleeve labeling.No more cup separating and feeding by hand. With cup rim separating screws, cup width and height adjustable

1、Technical Parameter

A. Auto cup Feeder

1. Tremendously raise the efficiency of cup feeding before sleeve labeling.No more cup separating and feeding by hand.

2. With cup rim separating screws, cup width and height adjustable

3. Suitable for different kind of cups of different diameter

4.stable cup stack separation into single cups by specially designed belt and screw unit, fast and stable without damaging cup body and rim

5. Vacuum system for cups landing on conveyors stably

6.Free of remaining any cups on cup feeder when change to another cups

1. Frame Dimension(L*W*H)1500mm*1200mm*1800mm

2. Vacuum blower underneath the Conveyor

3. Auto Cup separator Head, Width and Height adjustable

4. Suitable for Different kind of cups of different diameter

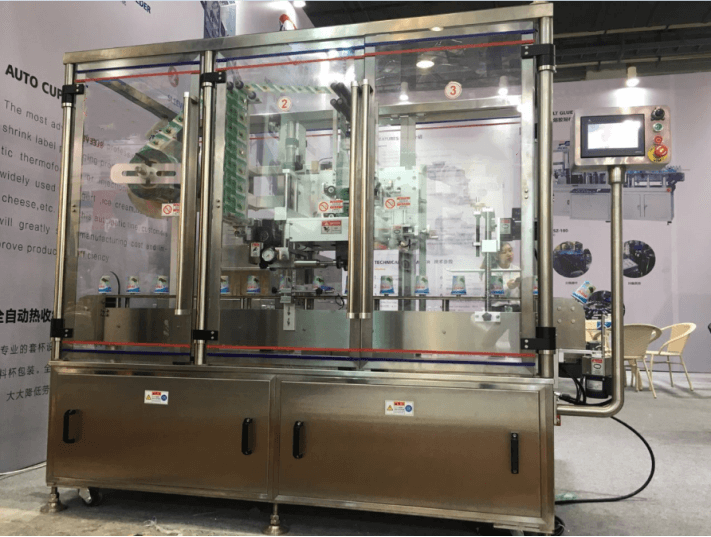

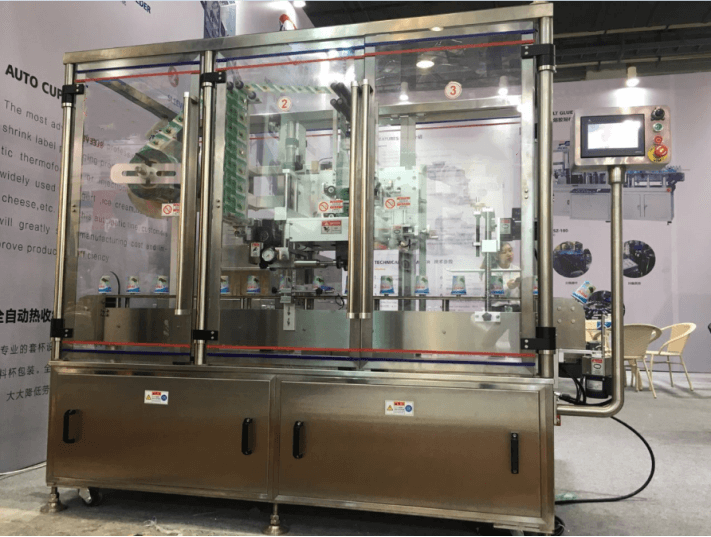

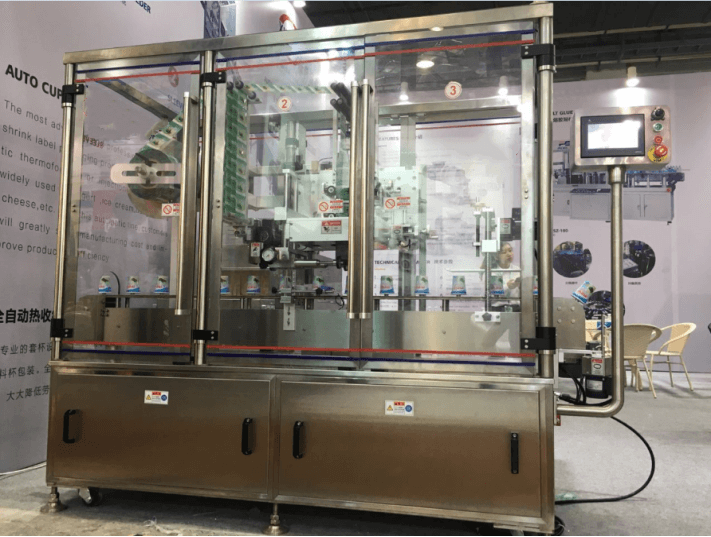

B、CUP Label Sleeving Machine

Main Engine of the cup shrink sleeve labeling line. Automatically separate the distance of the cup equally then precisely cut and sleeve labels onto every single cup which is put upside down before entering heat shrink tunnels. It is suitable for sleeve labeling empty plastic thermoforming and injection cups of different shapes and dimensions.

(1) Main machine size:1740L x 1000W x 2100H mm

(2) Main Body: SUS304 Stainless Steel

(3) Weight:about 500kgs (main machine)

(4) Bottle diameter Range (Blade Plate):Φ20~Φ50mm,Φ50~Φ95mm,Φ95~Φ130mm, one dimension can choose from three options, the special specification can be made to meet customers’ demands.

(5) Label Material: OPP, BOPP, PVC, PE, PET, ETC

(6) Label height:25mm ~ 300mm

(7) The thickness of label:0.03mm ~ 0.13mm

(8) Sleeve reel Inner core:5〝 ~10〝

(9) whole line Speed: 8000 per hour

(10) Voltage:3 phase / 220V or 380V(can be changed to customer's voltage format)

(11) Consumption power:main machine 2.5KW

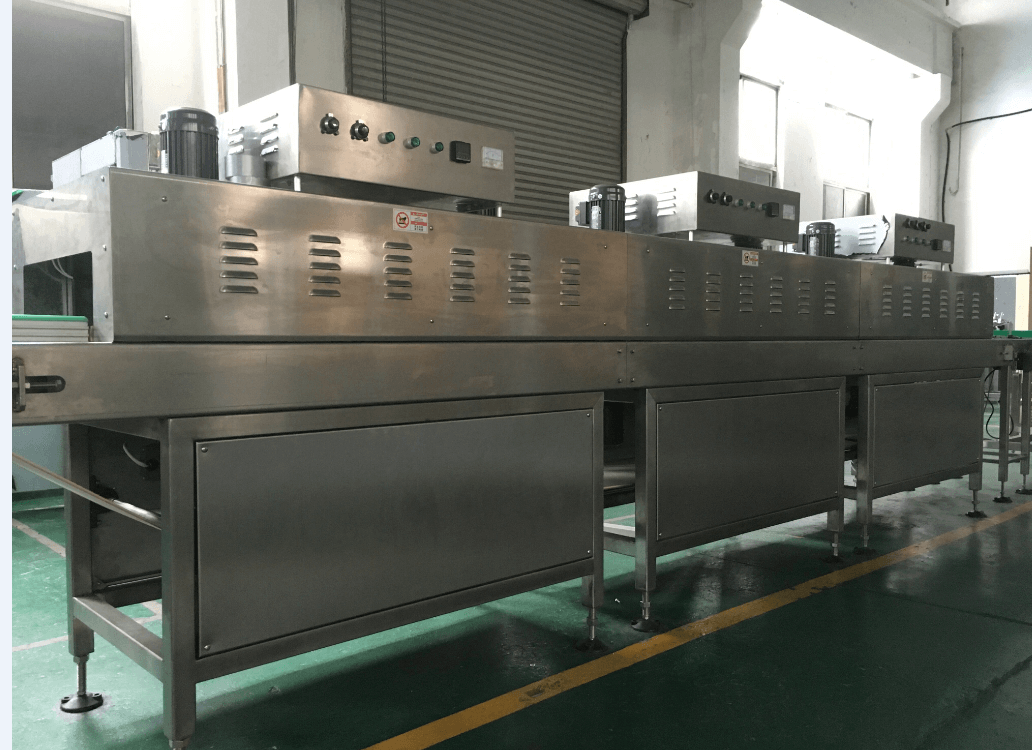

C、Electric Shrink Group Tunnel

Model:CO-SH1700W

Special Tailor-Made heat shrink tunnel model for empty plastic cups. The Tunnel line is made up of 3 in 1 structure with Low temperature recirculating hot air shrink inside which creates well-distributed shrink on cups of different dimensions and shapes. Totally free of tunnel height adjustment and cup mandrels to rotate inside tunnels.

(1) Main machine size:5400L x 500W x 1800H mm

(2) Whole Stainless Steel Body

(3) Blow Air Frequency Controlled

(4) Wider Entrance and Exit ,More Cups into it which makes the whole line speed faster

(5) Recirculating air ,lower temperature shrink cup sleeve

(6) Suitable for All kinds of cups shrink,No need to adjust the height when changing cups

(7) TEFLON chain ,Heat Resistant and solid material

(8) Solid body Frame ,Stronger and more stable

(9) Weight:about 240KGS each station

(10) Voltage:3 phase 380 / 220V

(11) Group Tunnel power Consumption:28KW

(12) Suitable for shrink variety container shapes, circle, square, oval-shaped, and curve-shaped etc.

(13) Accurately temperature control with +/- 5 degree.

D.Auto Cup Collector

1. Tremendously raise the efficiency of cup restacking and save labor cost ,No more manually cup restacking.

2. Fast and precise restacking process, suitable for different kinds of cups with different diameter and height

3. Mechanism make sure the cups are arranged neatly after restacking, easy for worker to pack into boxes.

4. Dust proof design, easy to clean

1. Main Frame(L*W*H) 2200mm*2000mm*1600mm

2. Smooth and fast cup stacking

3. PLC programming and invertor inside

4. Stainless Steel Collecting Platform

By continuing to use the site you agree to our privacy policy Terms and Conditions.