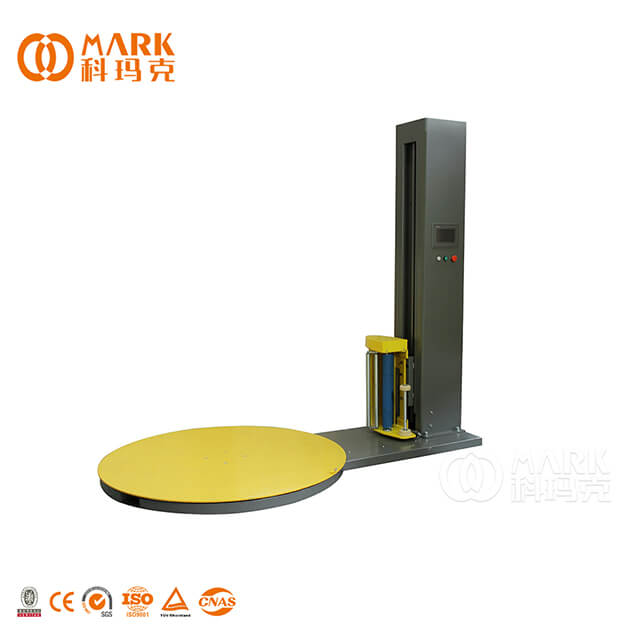

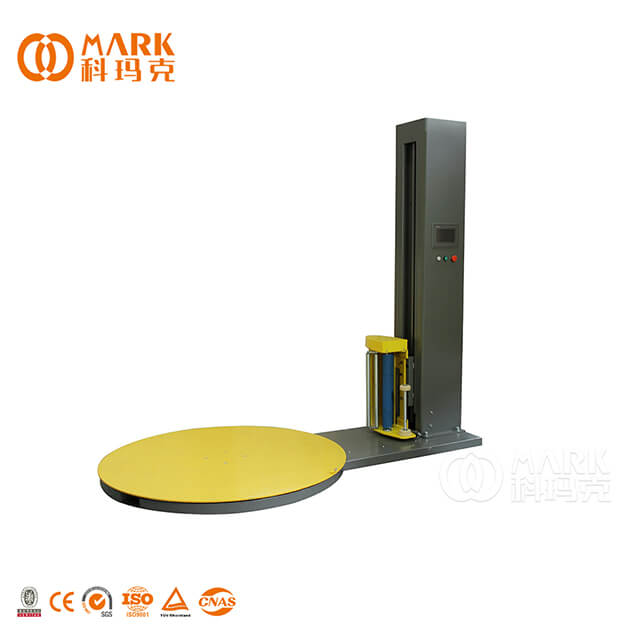

1.Automatical Winding Machine use LLDPE stretch film as the main packing material to wrap the bulk cargos stacked on the pallet 2.Film provides extra support during transportation and storage to protect them from dust, moisture or damage

Film Pallet Stretch Wrapping Machine

1.PLC programmable control, winding program optional, various parameters adjustable;Photoelectric switch automatically senses the height of goods

2.Pre stretching automatic film feeding mechanism

3.Slow start, slow stop and automatic reset of rotary table

4.The number of winding at the top and bottom is controlled separately

Technical parameters

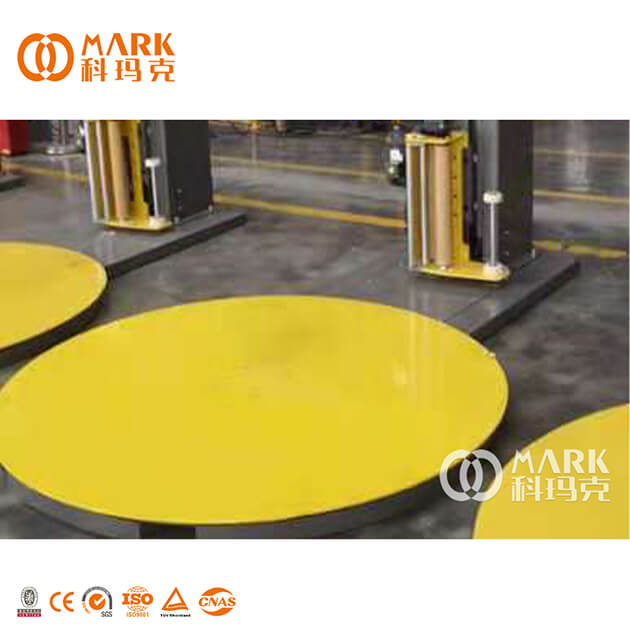

| Turntable diameter | 1650 mm |

| Packaging height | 2800mm |

| Turntable height | 80 mm |

| Turret load | 1500 kg |

| Operating weight | 650 kg |

| Overall power | 1.32 kw |

| Size | 2650*1650*3150 mm |

| Power supply voltage | 220 V, three-phase 60 Hz |

| Turntable speed | 0-12 rpm |

The rotary table is made of pure steel with high wear resistance.

The pre stretching mechanism can reach 250% and reduce the film consumption

The film frame is made of pure cast aluminum, light and stable. Wear resistant rubber roller is selected for long service life

Main components (selection of electric control system)

| PLC | (Siemens) (Germany) |

| Touch screen | (Kunlun Tongtai) (Taiwan) |

| Rotary frequency converter | (Siemens) (Germany) |

| Lifting frequency converter | (Siemens) (Germany) |

| Pre pull frequency converter | (Siemens) (Germany) |

| Travel switch Schneider | (France) |

| Photoelectric switch | (doublefour) (Germany) |

| Proximity switch | (Phoenix) (Taiwan) |

| Film frame lifting reducer | (Deli) (China) |

| Rotary reducer | (CUHK) (China) |

| Membrane frame pre pulling motor | (CUHK) (China) |

By continuing to use the site you agree to our privacy policy Terms and Conditions.