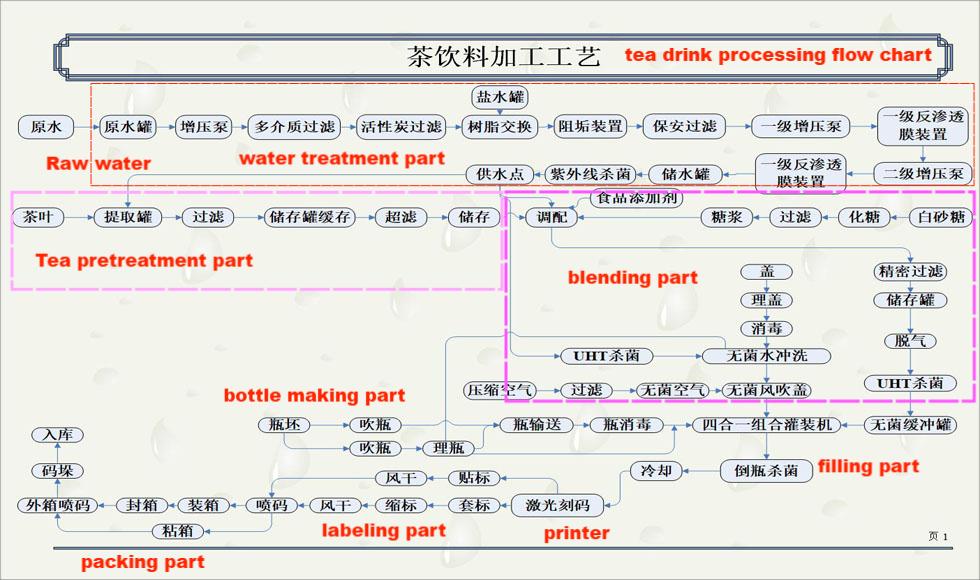

Here Comark shows you the tea production process.

1. Product overview of tea beverage production line:

Tea beverage refers to the tea soup made by soaking tea leaves with water, through extraction, filtration, clarification, etc. made products.

2. Classification of tea beverage production line:

Tea beverages are divided into tea soup beverages and flavored tea beverages according to their raw and auxiliary materials. Tea soup beverages are further divided into strong tea type and light tea type. Flavored tea beverages and other tea beverages.

Beverages are mainly made of common black tea, green tea, oolong tea or Chinese herbal medicine with specific effects on the market.

According to different requirements for product storage and packaging, PET plastic bottles, glass bottles and cans can generally be used in packaging forms.

3.Tea beverage production line process points:

a. Raw material selection

When choosing tea, it should be noted that different types and origins have a greater impact on the flavor of tea. The main component of tea soup beverage is tea extract, or tea juice, tea soup, so the quality of tea varieties and quality directly affects the quality of beverages. The tea raw materials used for tea beverages are mainly black tea, oolong tea and green tea, among which black tea is the majority, followed by oolong tea.

b. Extraction

The particle size, extraction temperature, extraction time, tea water ratio and extraction method (equipment) of tea raw materials all directly affect the extraction rate of soluble substances and the quality of the extraction liquid, thereby affecting the aroma of tea beverages and the concentration of active ingredients.

c. Filtration and separation

Before preparing the tea beverage, it needs to be filtered. In addition, the beverage containing milk tea should be homogenized after filtration before heating (generally, a high-pressure homogenizer is used for homogenization, the pressure is controlled at 20-25Mpa, and the temperature is 80-85°C).

d. Clarification

In the processing of tea beverages, flocculation and precipitation of tea polyphenols will occur in the process of extraction and high temperature. In order to obtain a tea beverage with stable quality and good quality, it is necessary to remove the produced precipitates by methods such as clarification.

e. Concentrate

At present, the reverse osmosis method is mainly used to concentrate tea juice. Usually, 5-10g/L cellulose powder is added to the tea soup. After reverse osmosis is used to concentrate the tea soup to a specified concentration, the cellulose in the tea soup is removed by filtration and centrifugal separation to obtain strong tea juice. The strong tea soup can be used as a base for preparing tea beverages, or it can be further dried to make instant tea.

f. Reconcile

Since tea soup is easily oxidized and browned, which affects the flavor of tea beverages, antioxidants (such as ascorbic acid and its sodium salt, erythorbic acid and its sodium salt) need to be added. If the tea beverage is too acidic, sodium bicarbonate is often used to adjust the pH to 6-6.5. Under the premise that the flavor of the tea beverage allows, the pH should be lowered to effectively prevent the growth of microorganisms and improve the stability of chemical components.

g. Filling

The prepared tea soup raw materials are heated to 90-95 ℃, filled while hot, and then flushed with nitrogen and sealed. If aseptic packaging is used, it is sterilized and cooled before aseptic filling.

h. Sterilization

The pH of the tea soup drink is above 4.5, it is best to use high pressure sterilization. Generally, high temperature sterilization or high temperature instantaneous sterilization can be used to effectively kill botulinum spores in beverages and achieve the expected sterilization effect. In addition, radiation sterilization, microwave sterilization, high-pressure pulse sterilization and other non-thermal sterilization and other high-tech applications are gradually being promoted in the production of tea beverages.

By continuing to use the site you agree to our privacy policy Terms and Conditions.