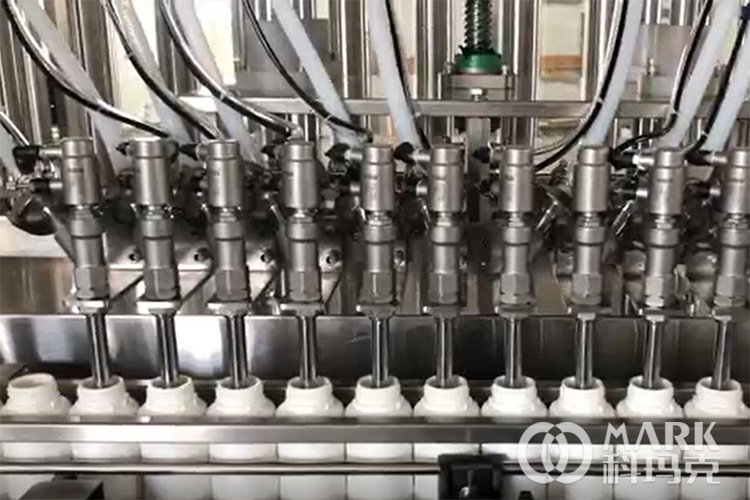

Facing the growing market demand, different types of filling machine equipment industries are quietly undergoing transformation, and the competition among manufacturers is also becoming increasingly fierce. From the perspective of material packaging, it can be divided into liquid filling machines, paste filling machines, powder filling machines and granular filling machines. Among them, liquid filling machines are used to fill various liquid equipment, including various beverages, edible oils and other liquid products.

With the development of automation technology, the automatic liquid filling machine has advanced automatic temperature control technology, easy operation and stable sealing quality. Widely used in various beverages, soy sauce liquid medium packaging, packaging UV sterilization, bag making, date printing, automatic filling, sealing, cutting, etc.

For example, since the liquid filling machine is filled with liquid, the container of the liquid filling machine must be kept clean, and the filling container must be strictly inspected and cleaned so that the filling agent is not contaminated, otherwise it will cause damage to the product quality. serious hazard.

In addition to cleaning the filling machine, it is also necessary to keep the filling workshop clean and tidy. Because in the production process, the most taboo is that the production line cannot operate normally due to the quality problem of the filling machine itself. Therefore, when using the filling machine, attention should be paid to sterilization, cleaning and low temperature filling. Keep the filler lines clean. All pipes, especially those in direct or indirect contact with materials, should be kept clean. Scrub every week, water every day, and disinfect every time; ensure that the filling machine is clean, and the material tank should be scrubbed and disinfected to ensure that the parts in contact with the material are free of oxide skin and bacteria. In the production process, the biological stability and sterilization of the bottled liquid should be guaranteed. Control the sterilization time and temperature to ensure the final effect, avoid excessive sterilization time or high temperature, reduce liquid oxidation, and cool as soon as possible after sterilization, so that the temperature does not exceed 35°C.

Before each operation of the filling machine, use 0-1℃ to reduce the temperature of the filling machine water tank and conveying pipeline. When the filling temperature exceeds 4°C, the temperature should be lowered first, and then the filling operation should be carried out. The use of thermal insulation tanks and constant temperature irrigation can keep the material at a certain temperature within the specified time of filling, so as to avoid the unstable operation of the filling machine due to excessive temperature changes.

In addition, the filling equipment should be isolated from other equipment, the lubrication part of the filling machine and the filling material part should be prevented from cross-contamination, and the lubrication of the conveyor belt should use special soapy water or lubricating oil.

If you want to know more, don't hesitate to contact Comark Machinery directly.

By continuing to use the site you agree to our privacy policy Terms and Conditions.