How to set up a juice plant factory? Here Comark provide some guidelines to consider when investing in juice project and purchasing a complete plastic bottled juice production line.

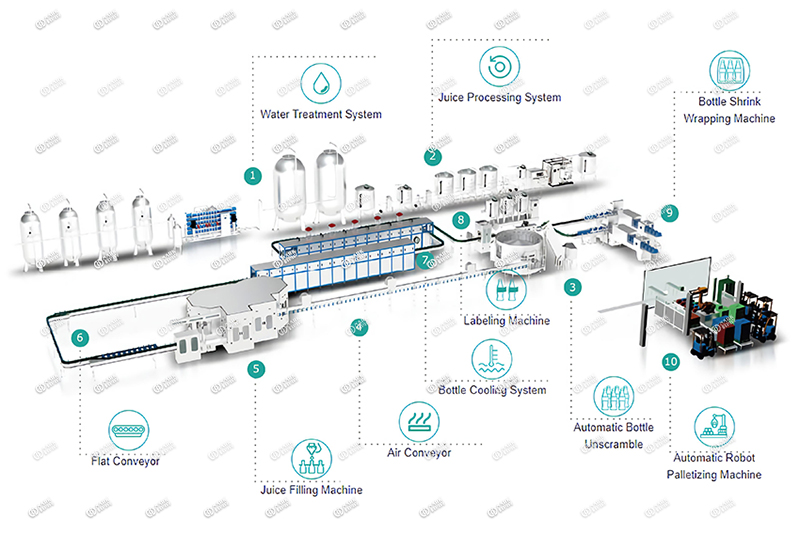

1. Production equipment of full set juice beverage production line:

Water treatment system: raw water tank, raw water pump, quartz sand filter, activated carbon filter, precision filter, reverse osmosis, ultraviolet sterilizer, water storage tank

Mixing system: sugar tank, double filter, centrifugal pump, mixing tank, syrup filter, homogenizer, vacuum degasser, tube/plate sterilization, CIP system

Filling system: three-in-one filling machine, spray system cooler, lighting testing equipment

Back-end packaging system: drying machine, printer machine, labeling machine, packing machine

2. Hot filling production equipment for juice and tea beverages:

Comark produces hot-filling series of juice and tea production management equipment, which can be used for automatic and safe production of bottled juice drinks, tea drinks, bottled pure water, mineral water and other still drinks. Advanced performance research, practical and beautiful, convenient operating system maintenance, high degree of automation development, is the first choice for hot-fill beverage production lines. The machine can adopt a bottleneck suspension, filling valve automatic lifting platform technology, can meet the technical capability requirements of hot filling below 95 degrees, and adopts advanced science and technology such as touch screen internal control, plc computer network control, and mixer control. SUS304 stainless steel is used between parts that are not in contact with the material. The main motor, reducer, main bearing, seals, electrical components and pneumatic components of the whole machine are all well-known brands. Production lines with various specifications can be customized according to different user requirements.

By continuing to use the site you agree to our privacy policy Terms and Conditions.