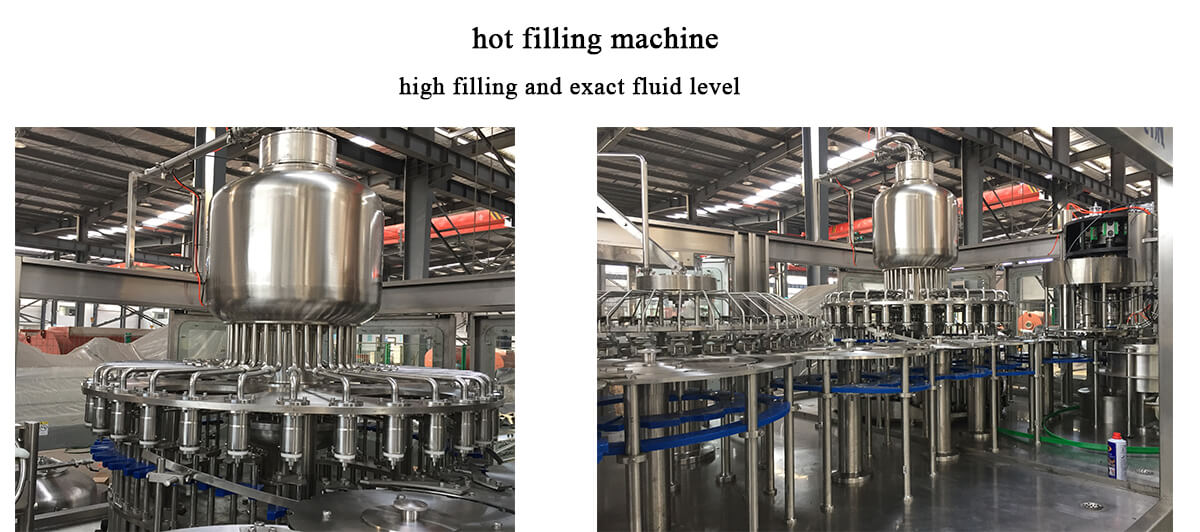

Automatic orange juice hot filling machine for PET bottle. The standard type of RCGF series hot filling machine is “3-in-1”, aiming at special production condition, one disinfectant rinser can be increased to be 4-in-1 monobloc. The system gives full consideration for beverage’s characteristics (e.g. it is easy to have foaming for tea beverage and mixed juice.) and main technical requirement of hot filling.

Application: juice, milk, vitamin drinks, functional beverage with particles, flesh, pulp, fruit pieces, etc.

Suitable for: PET bottles with all volumes and shapes

Filling system: gravity filling

Production capacity: 2,000BPH–20,000BPH (500ml)

Technical characteristics

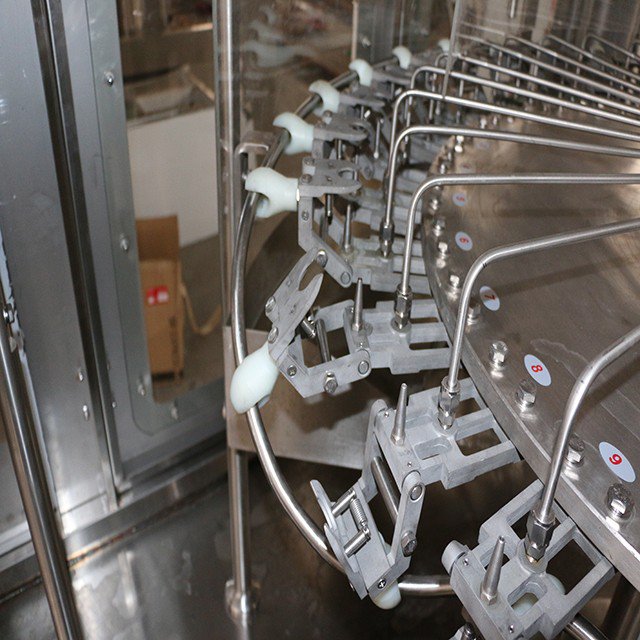

Full filling avoids the bottle distorted after cooling and reduces dissolved oxygen at the maximum degree.

Product storage hopper and feed system adopt reasonable product feed design (constant flow, constant pressure, no foaming).

Product hopper with reasonable structure (exhaust, fully close, the temperature can be detected)

The medium and high-speed line adopts a product distributor instead of a large liquid carousel, which can be cleaned completely by pressure cleaning with CIP.

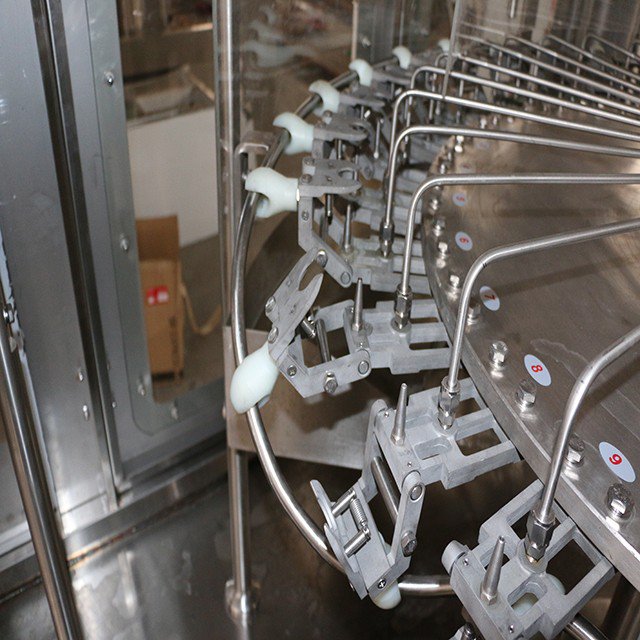

Sanitary filling valve system umbrella-flow type structure, high speed.

Perfect hot filling temperature control system.

Product recycling tank system with automatic product feed startup. perfect CIP system.

| Model | RCGF14-12-5 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-8 | RCGF40-40-10 | RCGF50-50-15 |

| Capacity | 3000-4000 | 4000-6000 | 8000-10000 | 12000-14000 | 16000-18000 | 20000-24000 |

Bottle Sharp | PET Round Bottle Or Square | |||||

| Bottle Dia | ∮50-∮115 | |||||

| Bottle Height | 150-320 | |||||

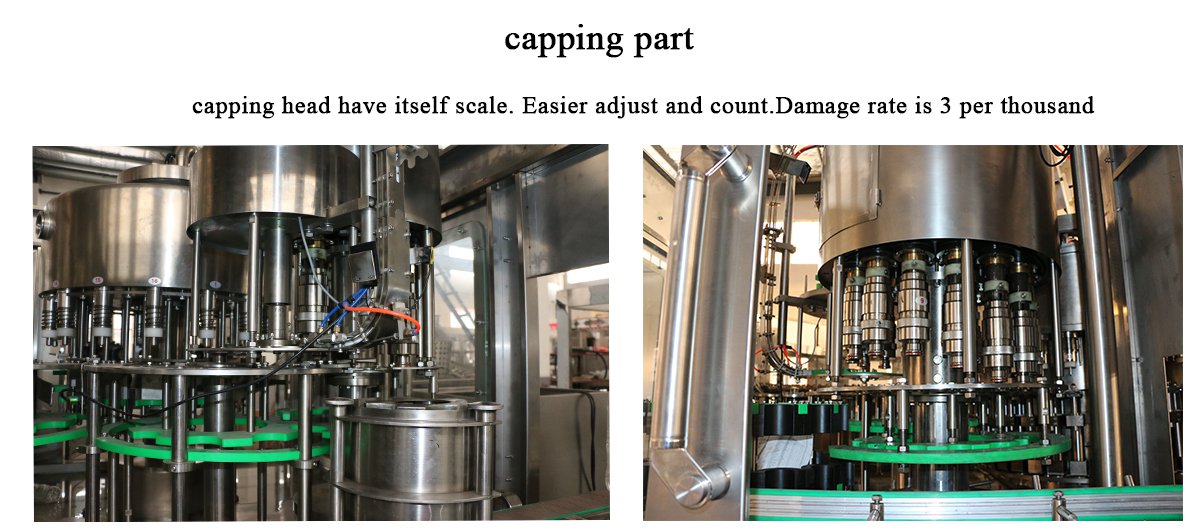

CAP | Plastic Screw Cap | |||||

| Power (kw) | 4.23 | 5.03 | 6.57 | 8.63 | 10.68 | 12 |

| Size (mm) | 2230*1630*2250 | 2360*1830*2250mm | 2900*2200*2250 | 3880*2200*2250 | 3700*3000*2350 | 4500*3300*2350 |

| Weight (kg) | 2200 | 2500 | 4200 | 6000 | 7000 | 9000 |

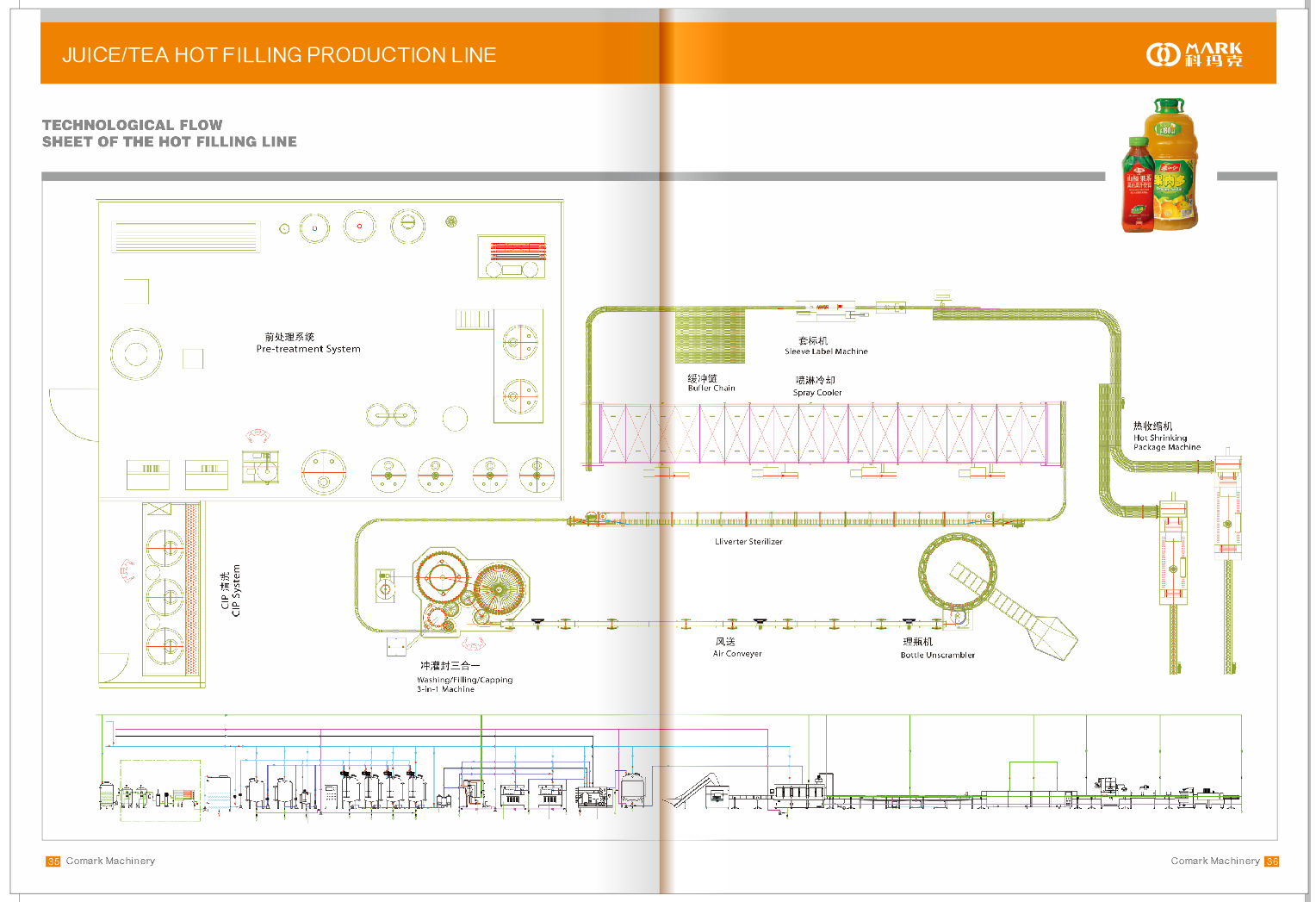

<1> The beverage processing system applies to beverage processing for hot filling line and CSD filling line.

<2> product's scope hot water system, sugar dissolving system ( simple syrup system ), concentrate system, blending system (final syrup system), CIP system, extraction system, kind of storage tank / valves / pipe / fittings, UHT system (plate / tubular type), and carbo-cooler / mixer (manual / automatic).

The tube(pipe) sterilize machine can take hot process on the liquid foods and beverage.

By continuing to use the site you agree to our privacy policy Terms and Conditions.